10pc pack TNMG-431-DM Triangle Negative Rake Coated Carbide Insert – Grade XAB749

The TNMG-431-DM Coated Carbide Insert (ISO: TNMG220404DM) is engineered for precision turning operations on CNC lathes and manual machines. Its negative rake triangular geometry ensures rigidity and stability during cutting, while the Grade XAB749 substrate, combined with a multilayer MT-TiCN + thick Al₂O₃ + TiN coating, delivers superior wear resistance and toughness.

This insert is specifically designed for finishing, semi-finishing, and light roughing of steels, cast steels, and stainless steels. The optimized chipbreaker geometry improves chip evacuation and reduces cutting forces, enabling longer tool life, consistent surface finish, and cost-effective machining.

Technical Specifications

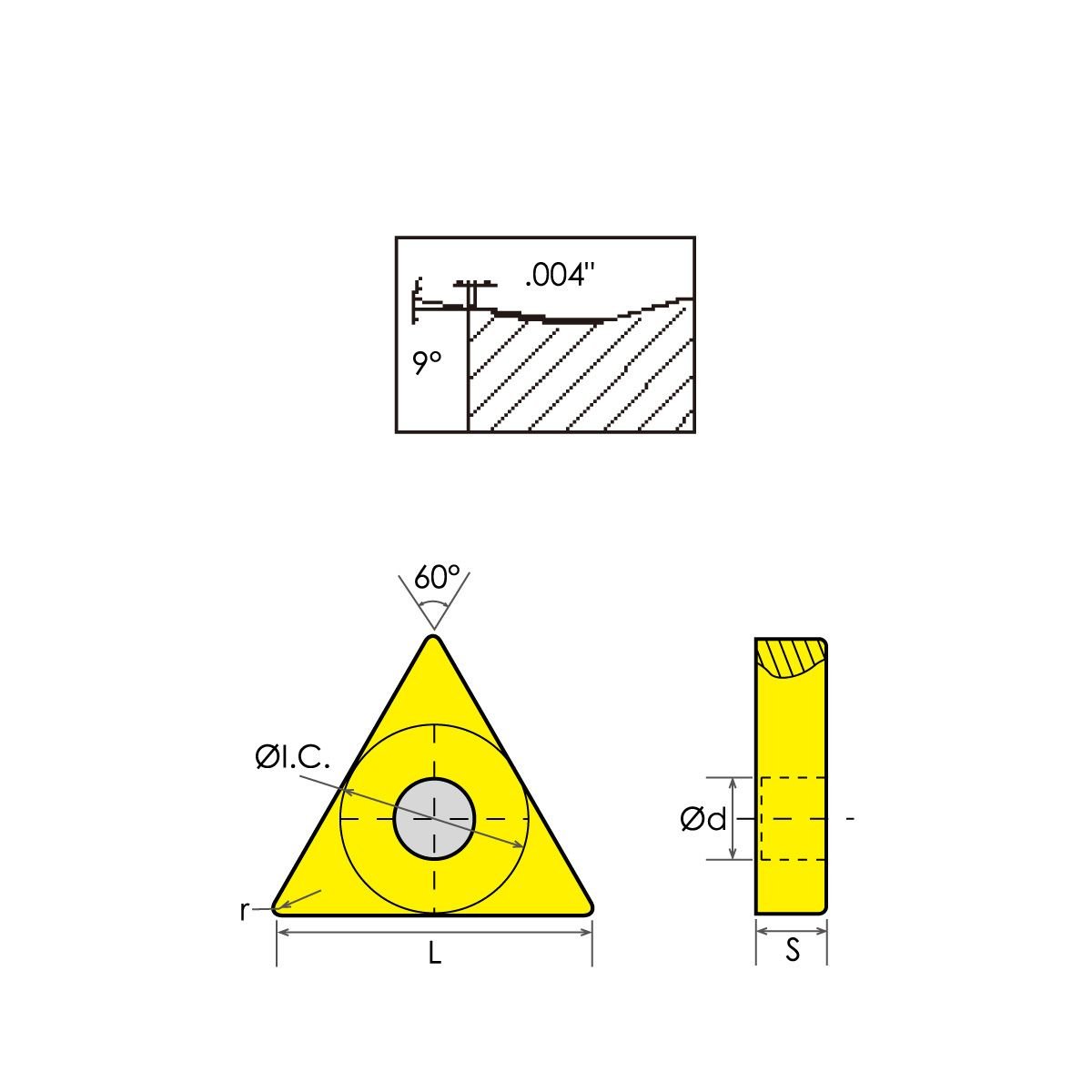

Insert Style: TNMG-431-DM (Triangle, Negative Rake)

ISO Insert No.: TNMG220404DM

I.C. (Inscribed Circle): 1/2″ (12.7 mm)

L (Length): 7/8″ (22 mm)

S (Thickness): 3/16″ (4.76 mm)

d (Hole Diameter): 13/64″ (5.2 mm)

r (Corner Radius): 0.0157″ (0.4 mm)

Grade: XAB749 – High strength carbide with MT-TiCN, Al₂O₃, and TiN multilayer coating

Weight: 0.02 lbs

Key Features & Benefits

✅ Negative Rake Geometry – Increases strength for stable machining.

✅ Premium Grade XAB749 – Combines toughness with excellent wear resistance.

✅ Advanced Coating – MT-TiCN + Al₂O₃ + TiN for thermal stability and longer tool life.

✅ Versatile Performance – Suitable for steel, cast steel, and stainless steel.

✅ Optimized Chipbreaker – Reduces cutting forces and improves chip evacuation.

✅ Cost-Effective Machining – Fewer tool changes, lower cost per part.

Recommended Cutting Conditions

| Material | Operation | Cutting Speed (Vc) | Feed Rate (fn) | Depth of Cut (ap) |

|---|---|---|---|---|

| Carbon Steel (≤200 HB) | Finishing | 180 – 260 m/min (590–850 sfm) | 0.08 – 0.20 mm/rev | 0.2 – 1.0 mm |

| Semi-Finishing | 160 – 220 m/min (525–720 sfm) | 0.15 – 0.30 mm/rev | 0.5 – 2.0 mm | |

| Alloy Steel (200–300 HB) | Finishing | 160 – 220 m/min (525–720 sfm) | 0.08 – 0.18 mm/rev | 0.2 – 0.8 mm |

| Stainless Steel (AISI 304/316) | Semi-Finishing | 120 – 180 m/min (395–590 sfm) | 0.10 – 0.25 mm/rev | 0.3 – 1.5 mm |

| Cast Steel / Ductile Iron | Light Roughing | 150 – 200 m/min (490–655 sfm) | 0.20 – 0.35 mm/rev | 1.0 – 2.5 mm |

(Values are recommendations and may vary depending on machine rigidity, coolant use, and workpiece conditions.)

Reviews

There are no reviews yet.