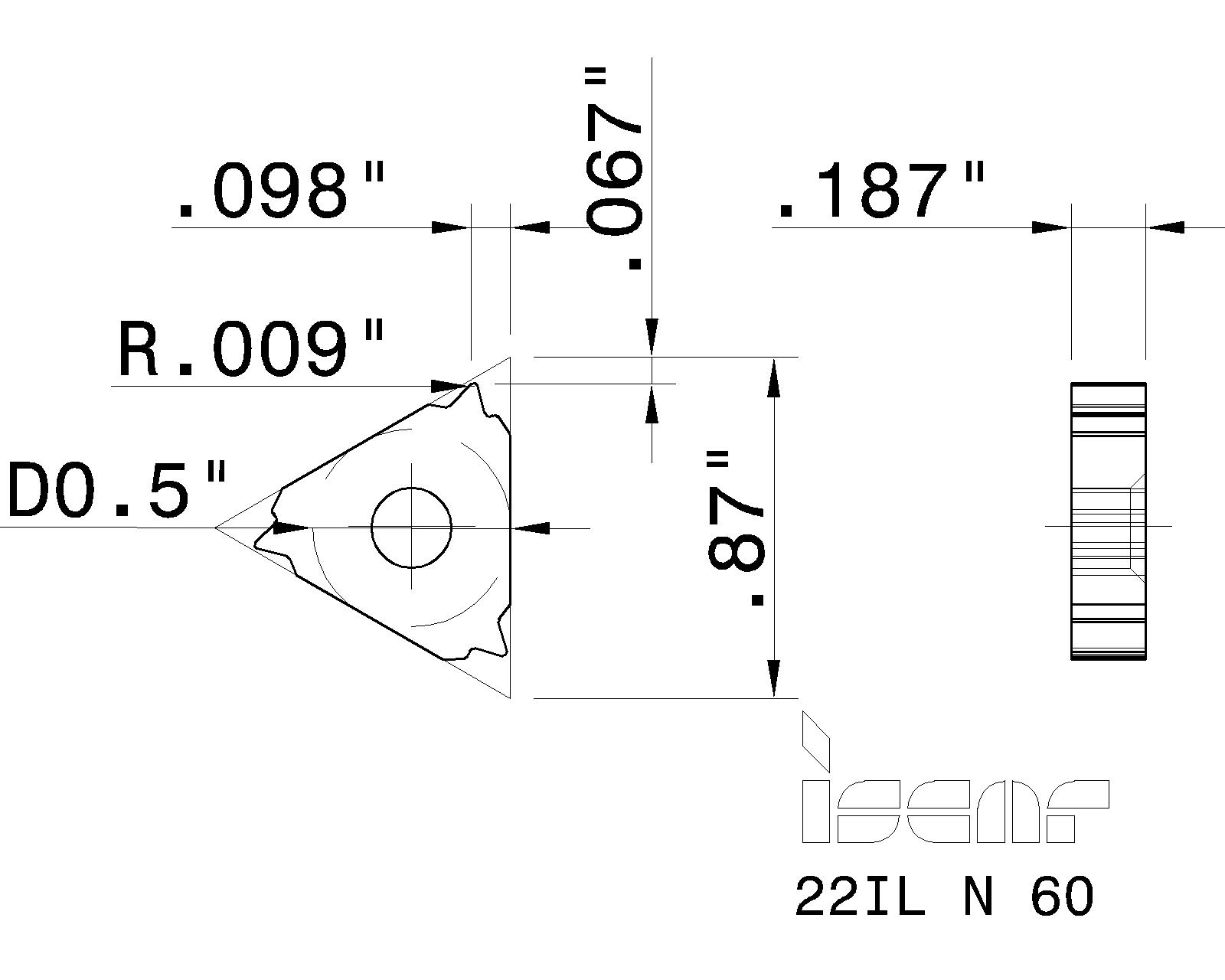

5pc 22IL N60 IC908 Iscar Threading Grooving Carbide Insert Triangle Left Hand

Sold in pack 5 Insert.

| IC | TPN (mm) | TPX (mm) | TPIX | TPIN | INSL | RE | PDY | PDX |

|---|---|---|---|---|---|---|---|---|

| .500 | 3.500 | 5.000 | 7.00 | 5.00 | .866 | .0087 | .07 | .10 |

Grade : IC908

A tough submicron grain size substrate with a PVD coating, recommended for general use for diverse operations on materials such as steels, alloy steels, austenitic stainless steel and high temperature alloys at a wide range of cutting speeds. Features high wear resistance and chipping durability.

| ISO Range – P/M/K | (P15-P30)(M20-M30)(K20-K30) |

| ISO Range – N/S/H | (H20-H30)(S10-S25) |

| Grade or Coating Type | PVD |

| Coating Layers | TiAlN |

Iscar is a leading manufacturer of cutting tools and inserts, including grooving and threading inserts. Some of the features of Iscar grooving threading inserts may include:

- Multiple cutting edges: Iscar grooving threading inserts typically have multiple cutting edges, which allow for longer tool life and increased productivity. These cutting edges may be designed for both internal and external threading operations, making them versatile for various machining applications.

- High-quality materials: Iscar grooving threading inserts are usually made from high-quality materials such as carbide or high-speed steel (HSS), which offer excellent wear resistance, toughness, and thermal stability. This ensures that the inserts can withstand the high cutting forces and temperatures generated during threading operations, resulting in reliable and consistent performance.

- Precision geometry: The geometry of Iscar grooving threading inserts is carefully designed to ensure optimal chip formation and evacuation, which helps prevent chip jamming and promotes smooth cutting action. The precision geometry also allows for tight tolerances and accurate thread profiles, resulting in high-quality threads with minimal runout and burrs.

- Coating options: Iscar offers a variety of coating options for their grooving threading inserts, such as TiN (titanium nitride), TiCN (titanium carbonitride), and TiAlN (titanium aluminum nitride). These coatings provide enhanced wear resistance, reduce cutting forces, and improve chip evacuation, resulting in longer tool life and improved surface finish.

- Versatility: Iscar grooving threading inserts are available in a wide range of sizes, thread profiles, and pitch options, making them suitable for various threading applications in different materials and machining conditions. They may also have adjustable features, such as thread pitch or cutting width, which allow for greater flexibility in machining operations.

- Easy indexing: Iscar grooving threading inserts are designed for easy indexing, allowing for quick and simple tool changes without the need for re-shimming or re-setting of tool heights. This reduces downtime and increases productivity in a manufacturing environment.

- Compatibility with Iscar tool holders: Iscar grooving threading inserts are typically designed to be used with Iscar tool holders, which provide secure clamping and precise positioning of the inserts. This ensures stable and accurate machining operations, resulting in consistent thread quality.

Overall, Iscar grooving threading inserts are known for their high-quality materials, precision geometry, coating options, versatility, and compatibility with Iscar tool holders, making them reliable and efficient tools for grooving and threading operations in a wide range of machining applications.