3 Piece 1/2″ Square Shoulder Coolant-Thru Indexable End Mill Set

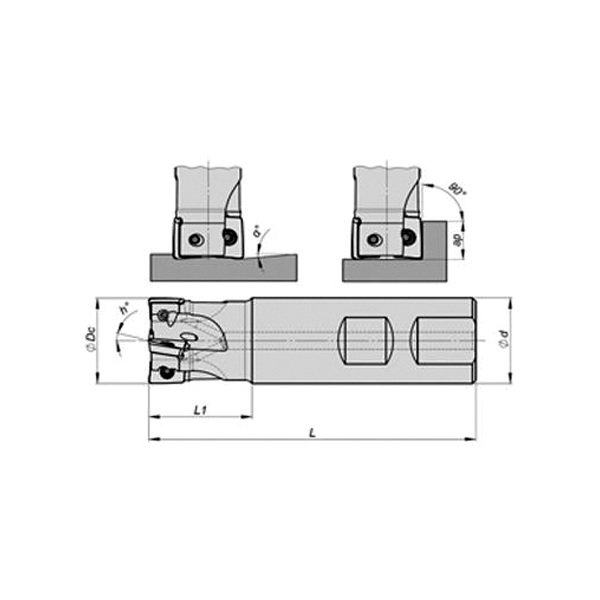

90° square shoulder.

Used for slotting and peripheral milling.

Excellent alternative to high speed steel, cobalt and carbide end mills for heavy material removal rates.

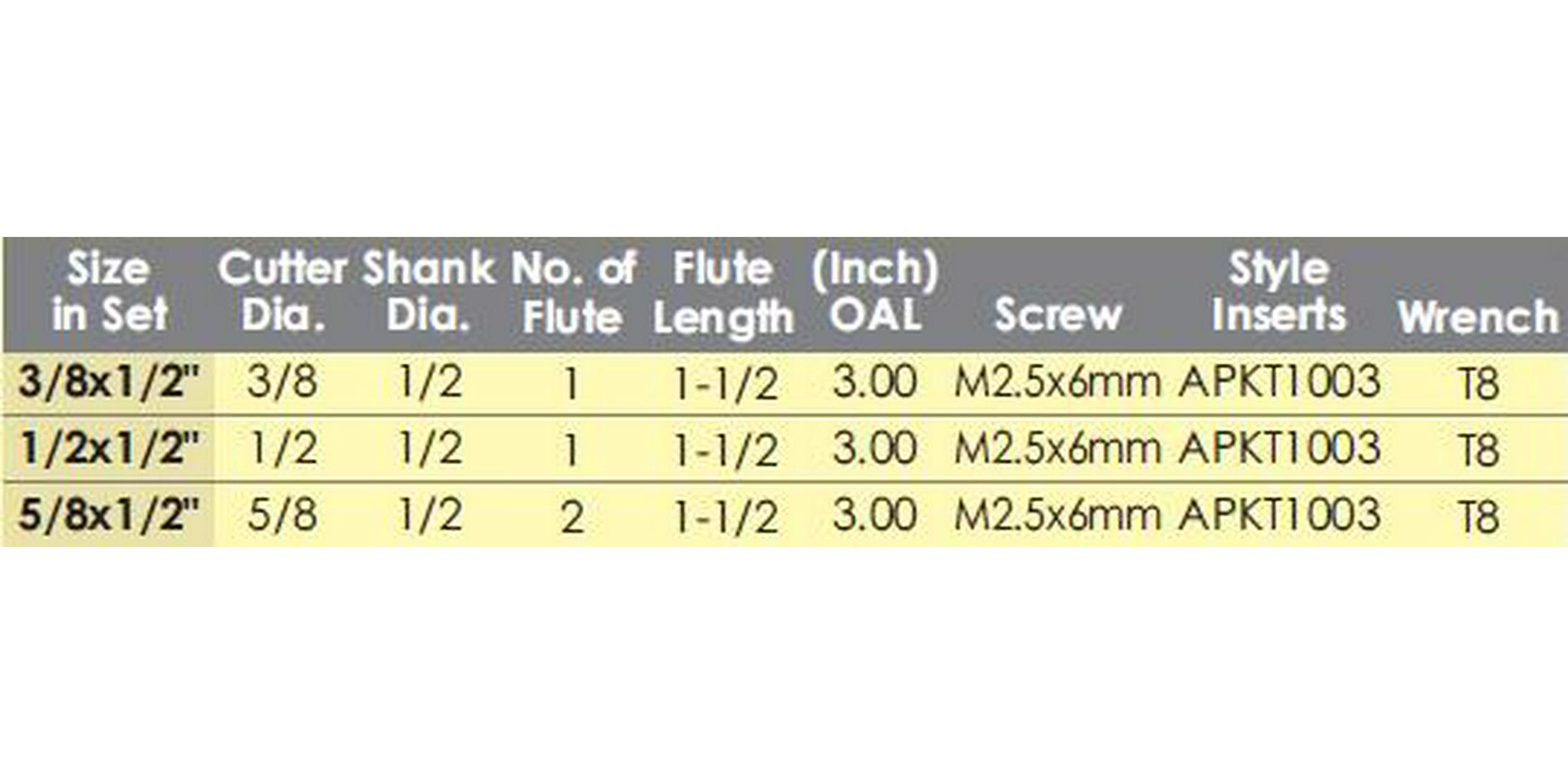

Uses standard APKT-1003 (#6010-4203) inserts with M2.5 X 6mm (#2100-0070) screw.

Inserts are not included.

Included:

– (1) 3/8” x 1/2” End Mill

– (1) 1/2” x 1/2” End Mill

– (1) 5/8” x 1/2” End Mill

🛠️ The Ultimate 3-Piece Indexable End Mill Set with 1/2″ Shank & Coolant-Thru: Performance, Precision & Durability

Introduction

In precision machining, especially when working with a variety of materials, having the right cutting tools isn’t a luxury—it’s essential. This 3-piece indexable end mill set with 3/8″, 1/2″, and 5/8″ cutting heads, a 1/2″ shank, coolant-through design, and 90° square shoulder geometry, is engineered for machinists who demand consistency, clean finishes, and long-term value.

Whether you’re running a CNC setup or a manual mill, this set is built to deliver.

🔍 Quick Specifications Table

| Feature | Specification |

|---|---|

| Shank Size | 1/2″ |

| Cutting Sizes | 3/8″, 1/2″, 5/8″ |

| Insert Compatibility | APKT Inserts (Indexable) |

| Shoulder Geometry | Square Shoulder – 90° |

| Coolant Capability | Coolant-Thru Internal Channels |

| Use Case | Slotting, Facing, Shoulder Milling |

| Material Compatibility | Steel, Aluminum, Alloys |

🔧 What Makes Indexable End Mills So Efficient?

Unlike traditional solid end mills, indexable tools use replaceable inserts that can be swapped out in seconds—no sharpening, no regrinding. Just lock in a fresh insert, and you’re cutting again.

💡 Coolant-thru channels direct fluid right to the cutting zone, improving chip evacuation and keeping the insert cooler under load. This extends the life of both the insert and the holder.

⚙️ Built for Real-World Workshop Use

After using this set in real workshop conditions, here’s what stands out:

“It’s ideal for my workshop. I ran a few cuts on aluminum and mild steel with my milling machine, and each pass was sharp, controlled, and incredibly clean. This tool absolutely delivers high-quality finishes on all fronts.”

You can feel the difference from the first cut:

⚡️ Less vibration = smoother finish

💎 Precise 90° corners without post-processing

🔄 Fast insert changeouts keep workflow tight

Whether you’re slotting steel plates or finishing aluminum brackets, this set saves time and reduces tool wear.

🧠 Use Cases: Where This Tool Shines

✅ Shoulder Milling: Clean, accurate 90° edges on structural parts

✅ Slotting & Pocketing: Stable geometry reduces chatter

✅ Facing & Surfacing: Uniform contact and excellent chip flow

✅ Material Flexibility: Handles aluminum, steel, and alloys with ease

This makes it perfect for:

CNC and manual machine operators

Prototype shops

Production machining

Technical schools and toolrooms

📌 Real-World Results

From precision cuts on small fixture components to bulk material removal on mild steel panels, this toolset has proven its versatility.

“I used the 5/8″ cutter for a surface clean-up on a steel mold base. It handled the job with ease—tight tolerances, zero deflection, and chips evacuated cleanly thanks to the coolant-thru design.”

The geometry and insert seat keep everything locked in tightly—even during aggressive passes. No wiggle, no wasted time.

❓ Frequently Asked Questions

Q: What makes a coolant-thru end mill better?

💬 It allows coolant to flow internally through the tool, reducing heat and improving insert life. This also helps with chip evacuation in deep pockets or during heavy milling.

Q: Can this set be used on stainless steel or harder materials?

💬 Yes. With quality APKT inserts and rigid holder design, it can handle tougher alloys, including stainless steel. Adjust speed and feed for optimal results.

Q: Are the inserts easy to change?

💬 Absolutely. Just loosen the screw with a torque wrench or hex key, replace the insert, and you’re back in action—no alignment or re-centering needed.

Q: What machines can this be used on?

💬 Any mill that accepts a 1/2″ shank—manual or CNC. It’s highly versatile and compatible with collet systems or end mill holders.

✅ Final Thoughts

If you’re looking for a toolset that balances precision, speed, and durability, this 3-piece indexable end mill set is a powerful addition to your workshop. Its coolant-thru design and 90° shoulder geometry provide clean cuts, longer tool life, and a better overall machining experience.

Whether you’re prototyping, producing, or repairing, this set helps you work faster—and smarter.