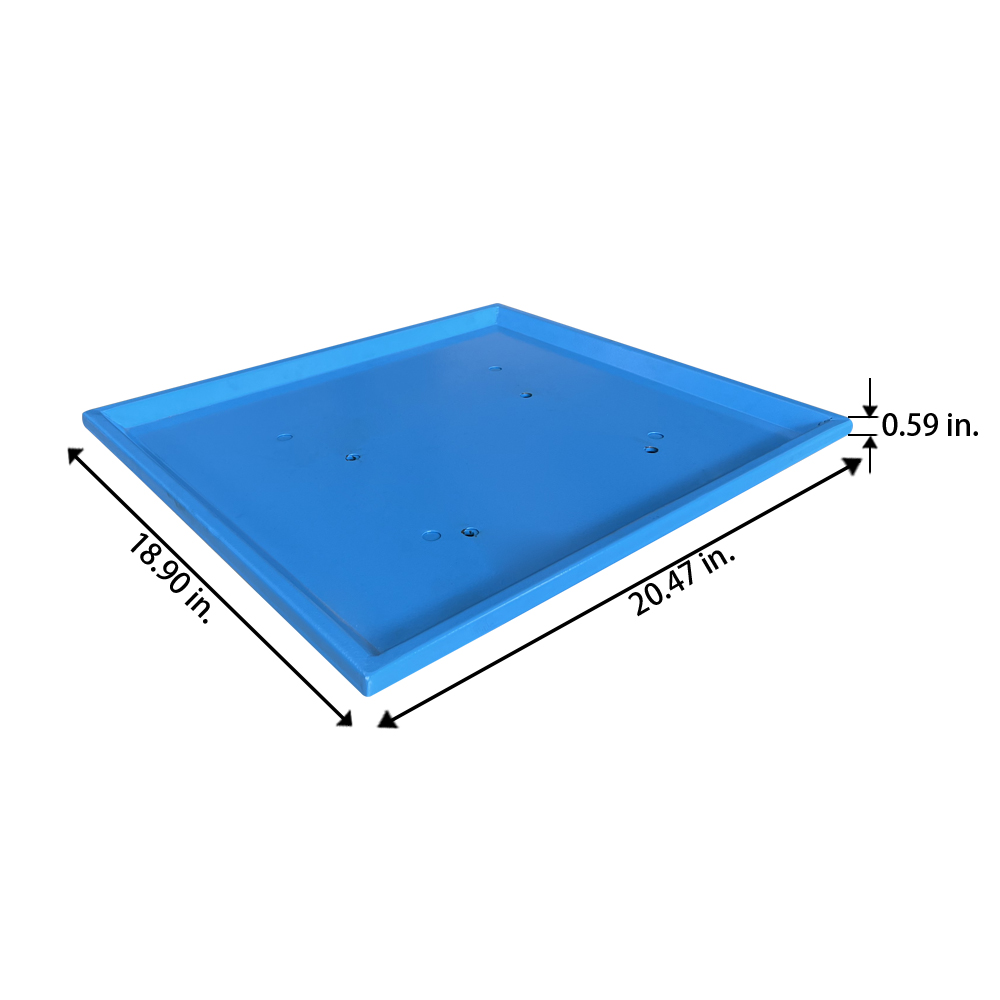

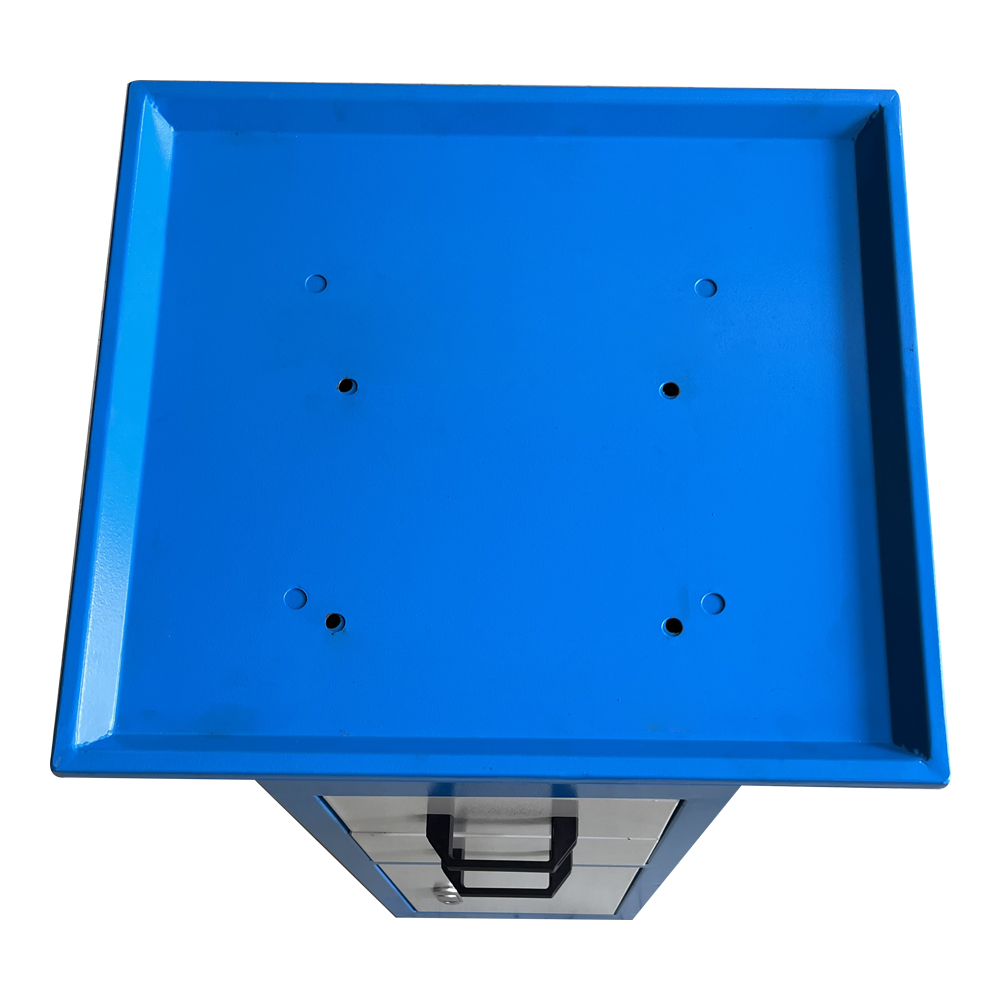

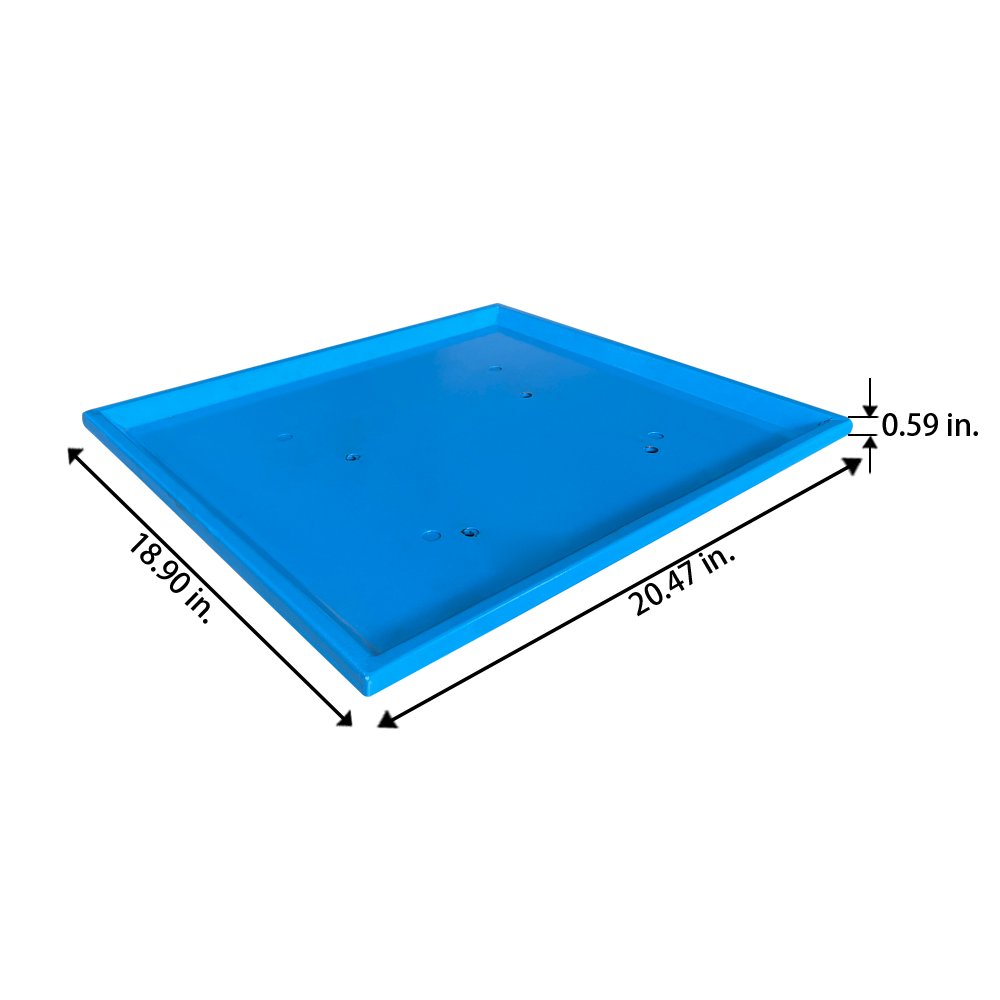

20.47″ x 18.90″ Oil Tray for VM18L and VM25 Milling Machine Replace Part

Can adapte in Grizzly and Precision Matthews milling machines please see all dimensions before Buy.

The oil tray in a milling machine serves a crucial purpose in the overall functionality and maintenance of the machine. Its main functions are as follows:

Lubrication: The oil tray is responsible for holding and distributing lubricating oil to various moving parts of the milling machine, such as the slides, gears, and bearings. Proper lubrication is essential to reduce friction and wear on these components, ensuring smooth and efficient operation.

Cooling: Milling machines generate heat during operation due to the cutting action and friction between the tool and workpiece. The oil in the tray helps dissipate this heat, preventing overheating and potential damage to the machine.

Chip and Debris Collection: As the milling machine cuts into the workpiece, chips and debris are produced. The oil tray helps collect these chips and debris, keeping the workspace clean and preventing them from clogging or damaging the machine’s internal components.

When it comes to replacing the oil tray or any critical part in a milling machine, it is essential to follow the manufacturer’s guidelines and recommendations. Here are some reasons why replacing a damaged or worn-out oil tray is important:

Machine Performance: A faulty or damaged oil tray can lead to insufficient lubrication and cooling, which may result in reduced machining performance, increased tool wear, and poorer surface finishes on the workpiece.

Machine Longevity: Proper maintenance, including timely replacement of essential components like the oil tray, can extend the overall lifespan of the milling machine.

Safety: A compromised oil tray can lead to hazardous conditions, such as increased friction, overheating, or the accumulation of chips and debris, potentially causing accidents or machine malfunctions.

When considering the replacement of any part in a milling machine, it’s crucial to use genuine replacement parts from the manufacturer or reputable suppliers to ensure compatibility and maintain the machine’s performance and safety standards.