Carbide Insert AP Shoulder milling

Shoulder milling is a fundamental milling application that involves creating a plane and shoulder surface simultaneously. Traditional square shoulder mills typically feature a cutting edge angle of 90°. Ensuring the exact cutting edge angle is crucial to prevent offsets between milling paths.

Application

- Suitable for machining steel, stainless steel, cast iron, heat-resistant super alloys, titanium, hardened materials, aluminum, and non-ferrous materials.

- Ideal for finishing and medium roughing.

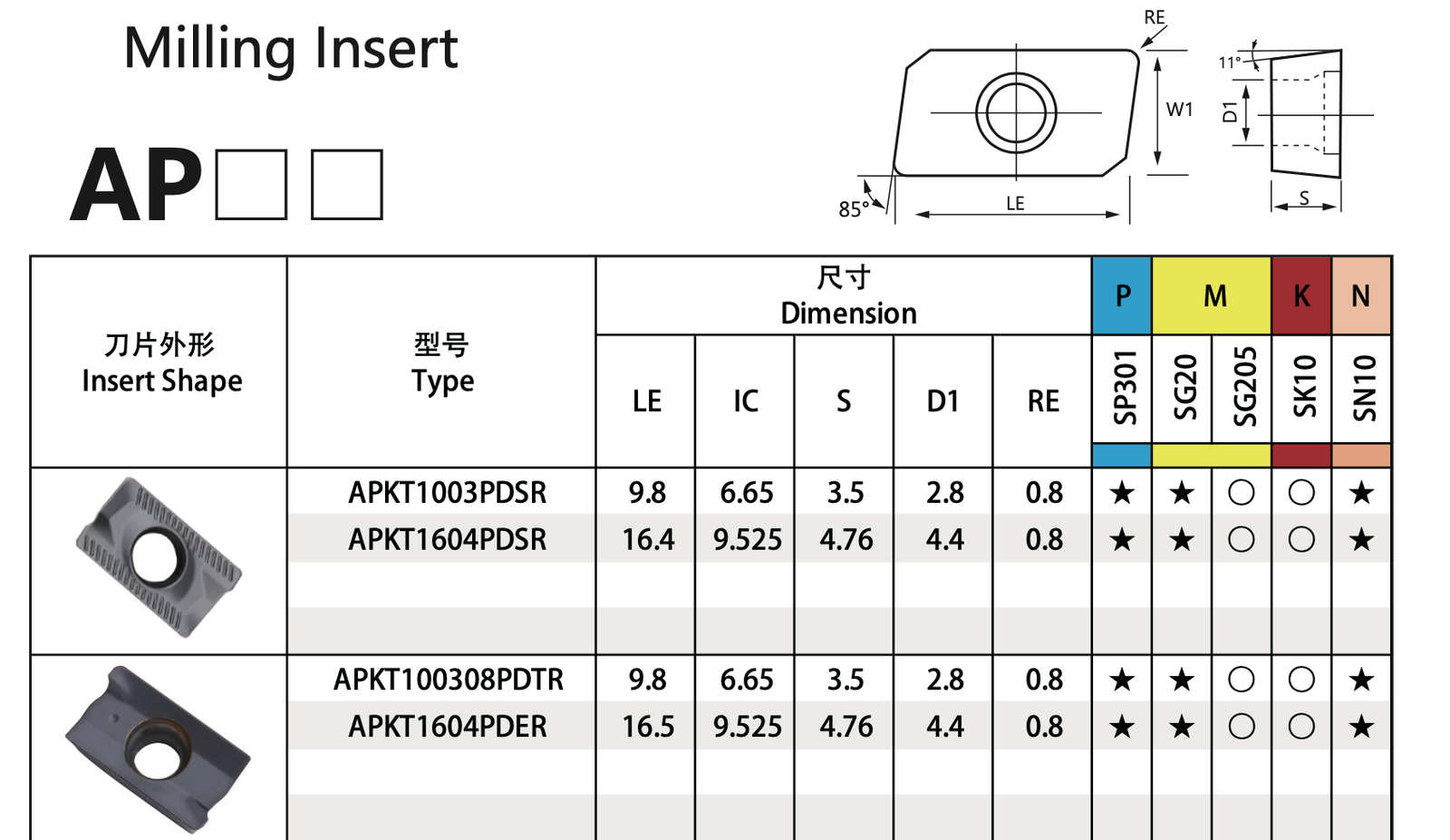

Technical Specifications:

- Applicable Material: Steel, Stainless Steel, Hi Temp Alloys

- Shape: 85° Parallelogram

- Application: Countersinking, Drill Mill, Facing, Milling Inserts, Plunging & Recessing, Rampdown, Shouldering, Slanted Shoulder & Chamfer, Slotting

- Maximum Feed per Tooth (fz(max)): 0.0059″/tooth

- Cutting Edge Length (L): 0.451″

- Insert Length (INSL): 0.451″

- Cutting Edge Material: Carbide

- Corner Radius (RE): 0.0315″

- Tool Type: Single-sided Inserts

- Depth of Cut Maximum (APMX): 0.315″

- Minimum Feed per Tooth (fz(min)): 0.0031″/tooth

- Insert Width (W1): 0.266″

- Cutting Edge Effective Length (LE): 0.404″

- Insert Thickness (S): 0.139″

- Measurement Type: Inch

- Coating: PVD (Silicon+AITiN)

- Body Material: Carbide

- Grade: SG20