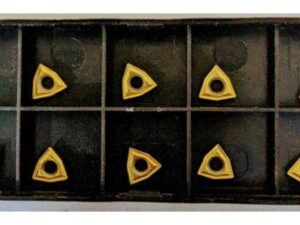

10pc TPMR322 Milling Carbide Insert TiN Coated Steel Grade

Brand Cobra Carbide

The carbide grade CM-14 (C-5) with a multi-layer coating of TiN/TiC/TiCN/TiN is specifically engineered for turning and milling operations, particularly when working with carbon steels, alloy steels, tool steels, and stainless steels.

Key Features:

1. Multi-layer Coating: The multi-layered TiN/TiC/TiCN/TiN coating provides a combination of hardness, toughness, and wear resistance. This structure enhances the tool’s durability and performance, especially in high-speed operations.

2. Extended Tool Life: The coating significantly extends the tool’s life compared to uncoated grades, making it suitable for long production runs without frequent tool changes.

3. Heat Resistance: The combination of materials in the coating offers excellent resistance to heat, allowing for higher cutting speeds and feeds without compromising the tool’s integrity.

4. Versatility: This grade is designed to handle a wide range of materials, making it versatile for different types of machining tasks, from roughing to semi-finishing operations.

Applications:

1. Turning: CM-14 is effective in turning operations, especially when machining carbon and alloy steels. Its multi-layer coating provides the needed hardness and wear resistance for extended periods of cutting, making it ideal for precision turning applications.

2. Milling: In milling operations, CM-14 offers superior performance due to its ability to maintain cutting edge integrity under high-speed conditions. This makes it suitable for milling various steels, including tool steels and stainless steels, with reduced risk of chipping and wear.