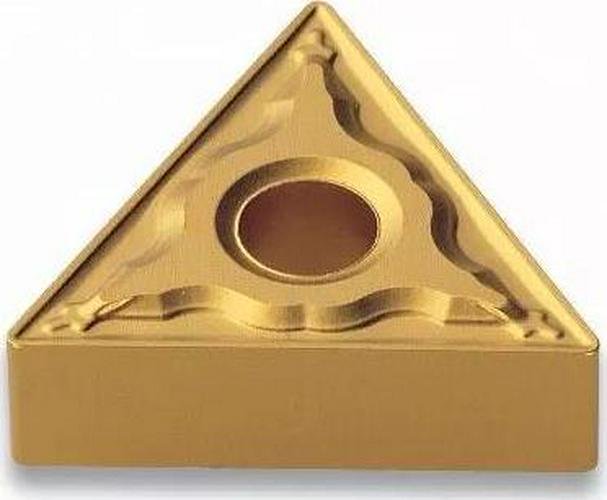

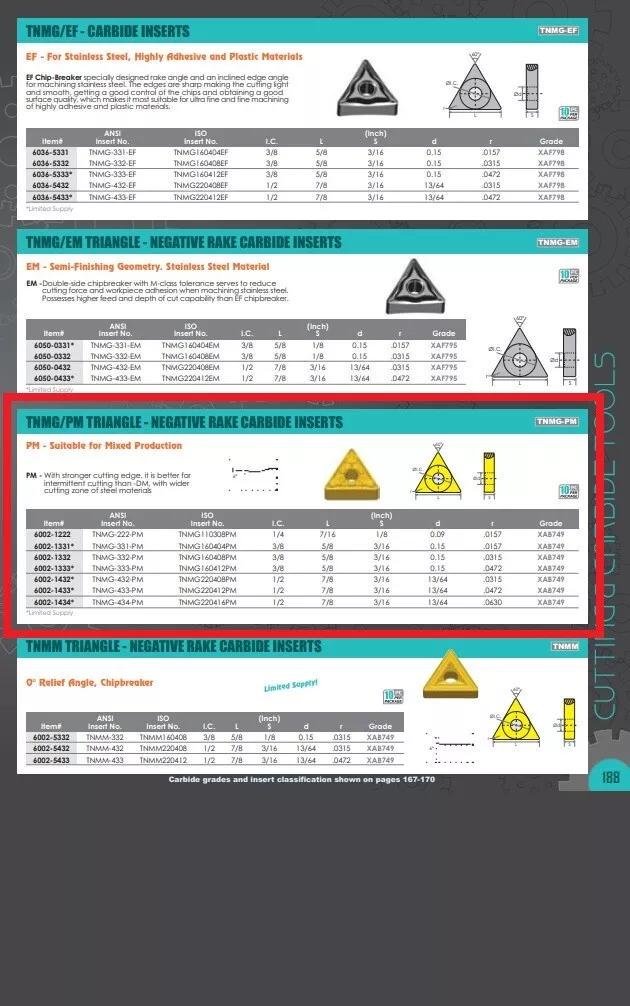

10pc TNMG-331-PM COATED CARBIDE INSERT (6002-1331)

TNMG-331-PM Triangle Negative Rake Coated Carbide Insert

Price is for 10pc carbide insert

Product Description:

Upgrade your machining capabilities with our premium TNMG 331 carbide turning inserts. Designed specifically for turning and milling applications, these inserts are ideal for machinists seeking precision and durability. Crafted from high-quality grade carbide, they offer superior wear resistance and prolonged tool life, making them perfect for both roughing and finishing operations.

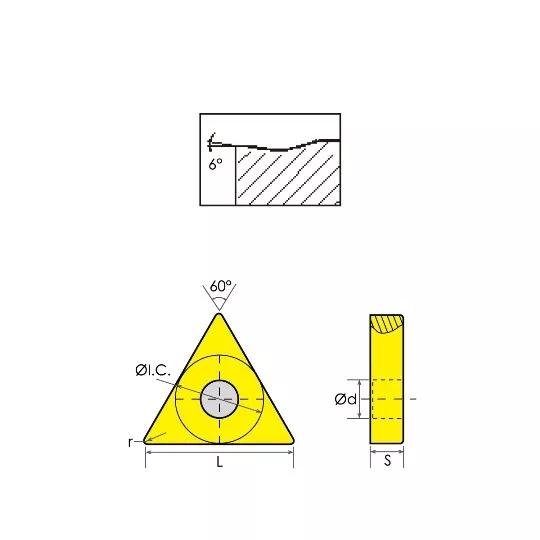

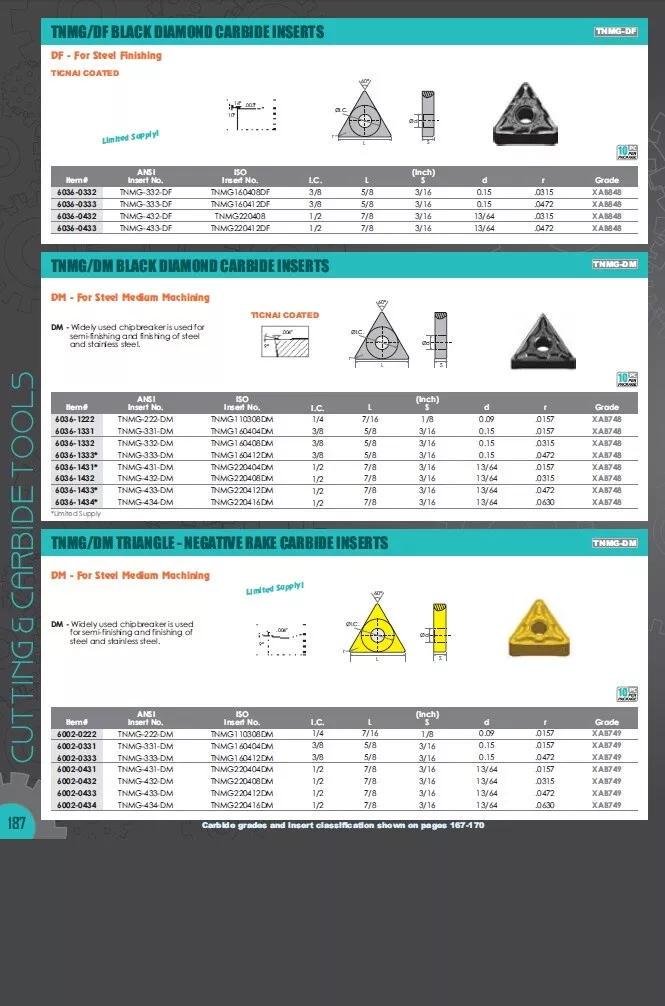

I.C. is 3/8″.

L is 5/8″.

S is 3/16″.

d is .15″.

r is .0157.”

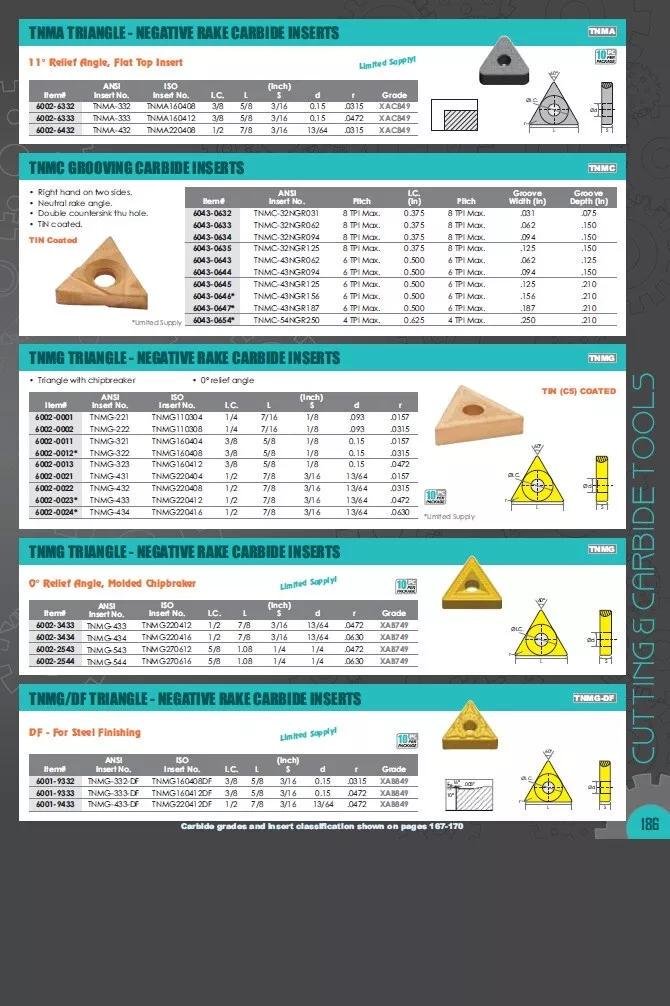

ISO Insert No. is TNMG160404PM.

Grade XAB749 offers a cutting edge with special strength and toughness, in an optimal combination with MT-TiCN, thick layer Al2O3TiN coating.

It is a suitable grade for a wide range of applications.

It is good for the finishing, semi-finishing and light roughing of steel, cast steel and stainless steel.

Features:

High-Quality Grade Carbide: Ensures durability and extended tool life.

Versatile Applications: Suitable for various turning and milling tasks.

Precision Machining: Excellent for achieving smooth finishes.

Compatible with Indexable Tool Holders: Fits a range of tool holders for flexible use.Optimized Geometry: Designed for efficient chip removal and minimal vibration.

Suggested Applications:

Turning Operations: Ideal for turning steel, stainless steel, and other metals.

Milling Operations: Perfect for face milling, end milling, and more.

Machinist Projects: Enhance productivity in custom machining tasks.

Suggestions:

Tool Compatibility: Ensure your tool holders are compatible with TNMG 331 inserts for optimal performance.

Machining Parameters: Adjust your machining parameters to match the insert’s capabilities for best results.

Maintenance: Regularly inspect inserts for wear and replace them to maintain machining precision.

Frequntly Customer Questions:

1.What grade of carbide is used in these inserts?

Our TNMG 331 inserts are made from high-grade carbide, ensuring enhanced durability and performance.

2.What is the diameter, thickness, and radius of these inserts?

The inserts feature a diameter of 0.375 inches, a thickness of 0.156 inches, and a radius of 0.031 inches, optimized for versatile machining applications.

3.Are these inserts compatible with my current indexable tool holders brand?

Yes, they are designed to fit a wide range of standard indexable tool holders.

4.Can these inserts handle high-speed operations?

Absolutely, their robust design makes them suitable for high-speed machining with minimal wear.

5.What types of materials can these inserts be used on?

These inserts are versatile and can be used on a variety of materials including steel and stainless steel.