10pc pack 2TNMG-432-PM Triangle Negative Rake Carbide Turning Insert – Grade XAB749 (ISO: TNMG220408PM)

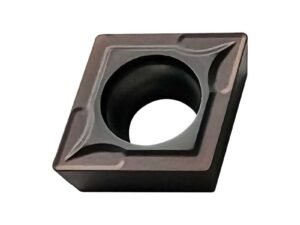

he TNMG-432-PM Coated Carbide Insert (ISO: TNMG220408PM) is a high-performance indexable insert designed for CNC lathes and manual turning operations. Its negative rake triangular geometry provides excellent strength and stability, making it ideal for precision machining at various cutting depths.

Built with Grade XAB749 carbide substrate and a multilayer coating of MT-TiCN, thick Al₂O₃, and TiN, this insert combines superior wear resistance, thermal stability, and toughness. The result is longer tool life, reduced tool breakage, and excellent surface finish across a wide range of applications.

Perfect for machinists, tool distributors, and industrial workshops, the TNMG-432-PM delivers consistent performance, cost efficiency, and reliable productivity in turning operations.

Technical Specifications

Insert Style: TNMG-432-PM (Triangle, Negative Rake)

ISO Insert No.: TNMG220408PM

I.C. (Inscribed Circle): 1/2″ (12.7 mm)

L (Length): 7/8″ (22 mm)

S (Thickness): 3/16″ (4.76 mm)

d (Hole Diameter): 13/64″ (5.2 mm)

r (Corner Radius): 0.0315″ (0.8 mm)

Grade: XAB749 – High-strength carbide with MT-TiCN, Al₂O₃, and TiN multilayer coating

Weight: 0.02 lbs

Key Features & Benefits

✅ Negative rake geometry ensures insert stability under heavy loads.

✅ Larger corner radius (0.0315″) for improved tool strength and smoother finishes.

✅ Grade XAB749 balances toughness and wear resistance for extended tool life.

✅ Advanced coating technology (MT-TiCN + Al₂O₃ + TiN) enhances heat resistance.

✅ Ideal for CNC machinists and production turning of steels, stainless steels, and cast steels.

✅ Lower machining costs thanks to reduced insert changes and reliable cutting edges.

Recommended Cutting Conditions

| Material | Operation | Cutting Speed (Vc) | Feed Rate (fn) | Depth of Cut (ap) |

|---|---|---|---|---|

| Carbon Steel (≤200 HB) | Finishing | 180 – 260 m/min (590–850 sfm) | 0.10 – 0.22 mm/rev | 0.2 – 1.2 mm |

| Semi-Finishing | 160 – 220 m/min (525–720 sfm) | 0.18 – 0.30 mm/rev | 0.5 – 2.2 mm | |

| Alloy Steel (200–300 HB) | Finishing | 160 – 220 m/min (525–720 sfm) | 0.12 – 0.24 mm/rev | 0.3 – 1.0 mm |

| Stainless Steel (AISI 304/316) | Semi-Finishing | 120 – 180 m/min (395–590 sfm) | 0.15 – 0.28 mm/rev | 0.4 – 1.8 mm |

| Cast Steel / Ductile Iron | Light Roughing | 150 – 200 m/min (490–655 sfm) | 0.22 – 0.35 mm/rev | 1.0 – 2.8 mm |

(Cutting values depend on machine rigidity, setup, and coolant conditions.)

Reviews

There are no reviews yet.