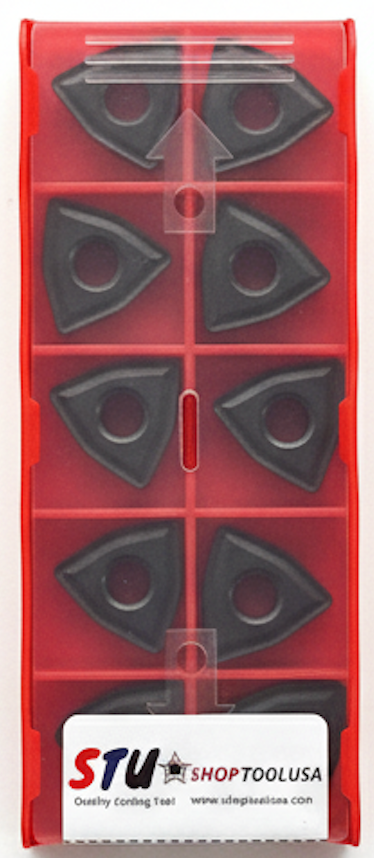

10pc WNMG080412 SK8010 CVD Coated Carbide Turning Insert (ISO K)

The WNMG080412 SK8010 indexable insert is a premium tooling solution meticulously designed for the rigorous demands of machining abrasive Cast Iron. Its specialized grade and geometry deliver superior wear resistance, making it the ideal choice for high-speed, stable finishing and semi-finishing operations.

Technical Characteristics

| Specification | Value | Technical Detail |

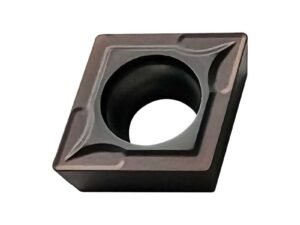

| ISO Code | WNMG 080412 | W (80° Trigon), N (0° Clearance), M (M-Tolerance), G (Double-sided), 08 (Cutting Edge Length), 04 (Thickness), 12 (Nose Radius $R\epsilon = 1.2\text{ mm}$) |

| Insert Shape | 80° Trigon (Triangular) | Highly robust negative geometry, providing six usable cutting edges for superior economy. |

| Grade (SK8010) | CVD Coated Carbide (ISO K10-K20) | A hard, low binder content, fine-grained substrate with high cubic content. Optimized for extreme abrasive wear resistance. Primary application: Cast Iron (K). |

| Coating | CVD (Thick TiCN + Textured Al${2}$O${3}$) | Highly durable CVD coating, engineered to withstand the abrasive nature of cast iron and high cutting temperatures. |

| Nose Radius ($R\epsilon$) | $1.2\text{ mm}$ | Larger radius for increased edge strength, improved heat dissipation, and superior surface integrity at higher feed rates. |

| Application Range | Finishing/Semi-Finishing | Excellent performance in stable, high-speed turning of Grey Cast Iron and Ductile Cast Iron. |

Key Benefits for the User

- Unmatched Abrasive Resistance: The specialized SK8010 grade is designed to combat the intense abrasive wear characteristic of cast iron, significantly extending the life of the cutting edge.

- Peak Performance at High Speed: The K10 grade focus (hard and wear-resistant) allows for substantial increases in cutting speed ($V_c$), driving down cycle times and boosting overall productivity.

- Maximum Edge Economy: The WNMG negative geometry provides six usable cutting edges (three per side), offering the lowest cost-per-edge in stable, high-volume production environments.

- Enhanced Surface Finish: The robust $1.2\text{ mm}$ nose radius aids in stabilizing the cut and reducing vibration, contributing to a smoother, high-quality finished surface.

Recommendations for Use

| Parameter | Recommended Range | Notes |

| Workpiece Material | Grey Cast Iron, Ductile Cast Iron (ISO K) | Primary Application. Also suitable for titanium and certain high-temperature alloys (verify chip breaker). |

| Depth of Cut (a_p) | 0.5\text{ mm}$ to $3.5\text{ mm}$ (Medium to Light) | Optimized for finishing and light semi-finishing to leverage the wear resistance. |

| Feed Rate (f) | 0.20\text{ mm/rev}$ to $0.60\text{ mm/rev} | Utilize higher feeds to maximize material removal without compromising finish due to the large nose radius (R\epsilon=1.2). |

| Cutting Condition | Continuous / Stable | Ideal for high-speed, continuous turning. Avoid heavy interrupted cuts. |

| Coolant | Dry Machining Preferred | Cast iron is typically machined dry to prevent thermal cracking and aid chip evacuation (SK8010 is well suited for high-temperature dry cuts). |

5 Possible FAQs (Frequently Asked Questions)

1. What is the main application of the SK8010 grade?

The SK8010 grade is a highly abrasive-resistant CVD-coated carbide designed specifically for high-speed finishing and semi-finishing of Cast Iron (ISO K materials), including Grey and Ductile Cast Iron.

2. Why does this insert have a 1.2 mm nose radius (Rϵ)?

The large 1.2 mm nose radius is used to increase the strength of the cutting edge and efficiently absorb heat. This allows for higher feed rates to be used while maintaining a good surface finish, which is crucial in high-volume cast iron production.

3. How many cutting edges does the WNMG insert provide?

The WNMG is a double-sided, 80° Trigon (Triangle) negative insert, providing a total of six usable cutting edges (three on the top face and three on the bottom face).

4. Can I use the WNMG080412 SK8010 for turning steel?

While possible in an emergency, the SK8010 grade is specialized for the high-abrasion wear of cast iron, not the crater wear typical of steel. A P-grade (like P25) insert would provide significantly better performance and tool life in steel.

5. Should I use coolant with this insert?

For machining cast iron with a specialized K-grade like SK8010, dry machining is strongly recommended. Using coolant can introduce thermal shocks, which can lead to micro-cracks and premature failure in hard, wear-resistant carbide grades.

Reviews

There are no reviews yet.