10pcs Carbide Insert APMT 1604PDER w/50 mm Indexable Tool Shell Face Milling Shoulder 90

Pack Included:

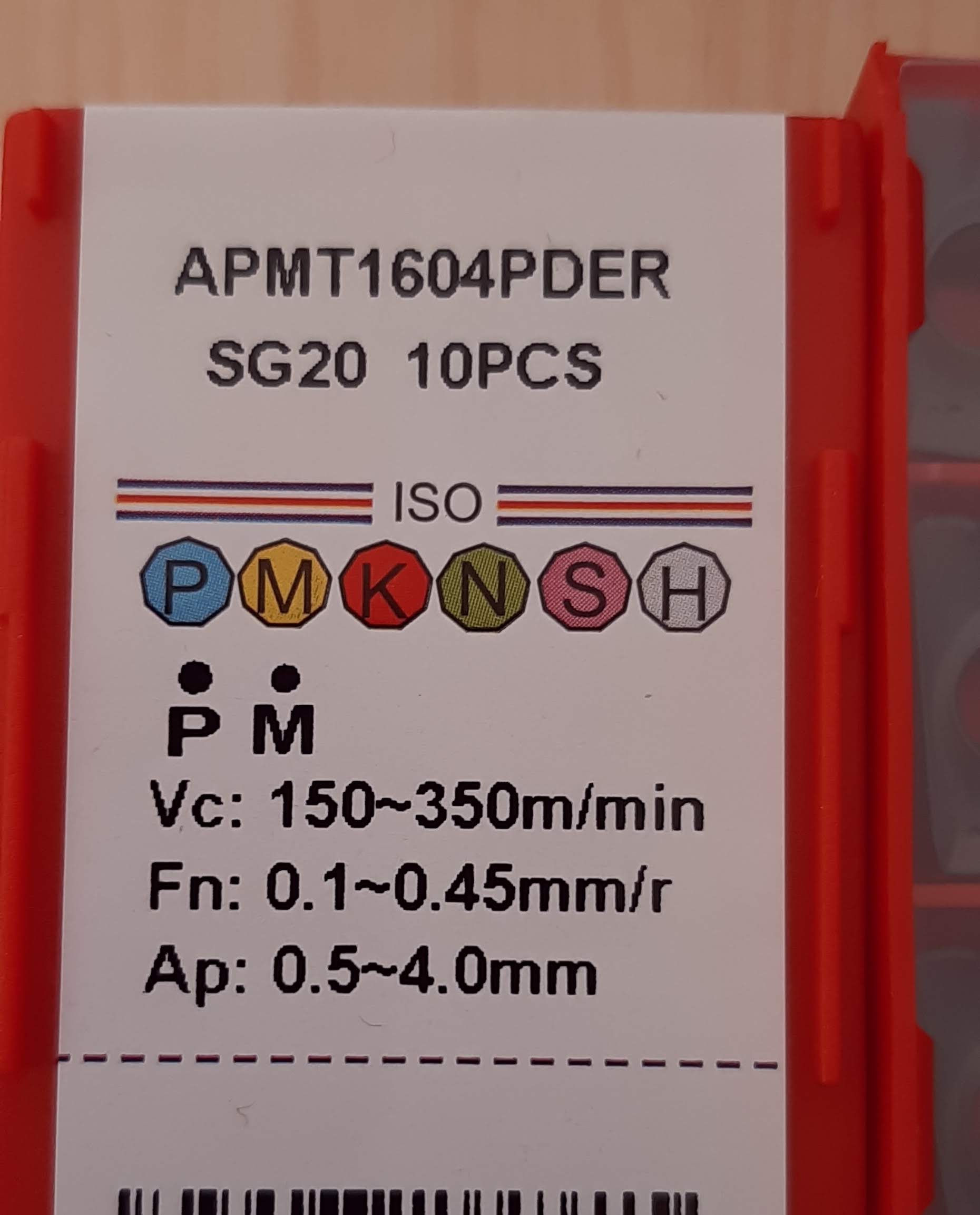

10 pcs Carbide Insert APMT1604PDER TiAlN GRADE SG20

1pc 2 inch Face Mill Square Shoulder 90 degree

1pc Wrench

Insert Shape & Angle Parallelogram

| Tool Material | Carbide |

|---|---|

| Insert Style | APMT |

| Insert Size | 1604 |

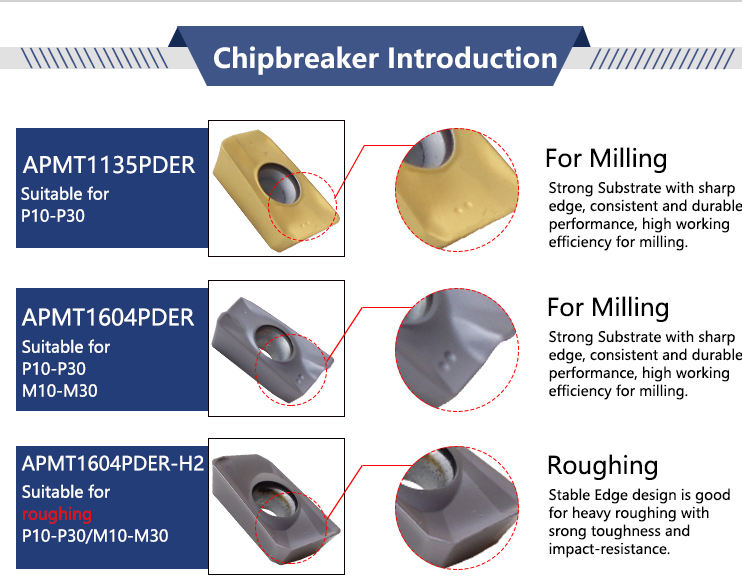

| Chipbreaker |

| ISO K CAST IRON | X |

|---|---|

| ISO M STAINLESS STEELS | X |

| ISO P STEEL | X |

| ISO S HRSA EXOTIC | X |

| Maximum Depth of Cut | 0.630″ |

| No. of Cutting Sides | 2 |

| Insert Thickness | 3/16″ |

|---|---|

| Insert Radius | 0.031″ |

| Relief Angle | 11° |

| Coating | PVD / TiAlN |

| Series | |

| Insert Hand | Right Hand |

| Insert Length | 0.646″ |

Grade | SP301/SG20/SG205 | ||

Workpiece | steel/hardened steel/ stainless steel/cast iron | ||

Coating | PVD coating | ||

Grade for Milling Inserts | ||||

GRADE | COATING | COLOR | WORKING MATERIAL | APPLICATION |

SG205 | PVD (Silicon+TiAlN) | purple | M10-M30 | Micro WC grain substrate with high Co maintain cutting edge strength and it has smallest coefficient of friction and good nano hardness with good thermal stability silicon coating. The grade is very good for interrupt turning and milling for stainless steel. |

SG20 | PVD (Silicon+AITiN) | grey black | M20-M40 | The fine WC micro grain substrate with high co content gives wonderful cutting edge strength. The PVD AITiN coating combines with good thermal stablility silicon, which has very small coefficient of friction and good nano-hardness. The grade is good at stainless steel semi-finishing turning, parting and grooving processing. Also, it is a preferred grade for steel and stainless steel milling and drilling. |

SP301 | PVD (Silicon+ TiN) | yellow | P10-P30 | The carbide substrate have good anti-deformation resistance and toughness. PVD TiN with silicon coating has very good surface quality and small friction with high hardness. It is suitable for semi-finishing and finishing steel processing for milling. |

Grade for Turning Inserts | ||||

GRADE | COATING | COLOR | WORKING MATERIAL | APPLICATION |

SP8025 | CVD (MT-TiCN+Al2O3+TiN) | golden yellow | P10-P30 | The carbide substrate have good anti-deformation resistance and toughness. MT-TiCN+Al2O3+TiN coating has very good surface quality and help to recognize wear easily. It is suitable for semi-finishing and finishing steel machining. |

SP8125 | CVD (Multi-TiCN+Al2O3) | black | P10-P40 | The carbide substrate have mild cobalt content and high cubic content, combining with thick TiCN and Al2O3, treated by sepcial technology after coating treatment, which gives inserts strong wearing resistance. It is prority for semi-finishing to finishing steel machining. |

SM8020 | PVD (Silicon+TiAlN) | purple | M10-M30 | Micro WC grain substrate with high Co maintain cutting edge strength and it has smallest coefficient of friction and good nano hardness with good thermal stability silicon coating. The grade is very good for interrupt turning and milling for stainless steel. |

SK8010 | CVD (thick TiCN+ textured Al2O3) | black | K10-K30 | The medium-coarse substrate combine with thick TiCN and textured Al2O3, after special coating treatment, it has strong wear-resistance. The grade is suitable for high-speed semi-finishing cast iron turning under stable working condition. |

Milling

| Work Piece Material | HB | Grade | V(M/Mim) | F(Mm/Z)) | |

| P | Low-Carbon Steel、 Soft Steel | ≤180 | SP8025 SP8125 | 190 (140-250) | 0.08 (0.04-0.15) |

| High-Carbon Steel、Alloy Steel | 180-280 | SP8125 SP8025 | 170 (130-250) | 0.08 (0.04-0.15) | |

| Alloy Tool Steel | 280-350 | SP8125 SP8025 | 150 (110-240) | 0.08 (0.04-0.15) | |

| M | Stainless Steel | ≤270 | SM8020 SG205 SG20

| 120 (80-190) | 0.08 (0.04-0.15) |

| K | Cast Iron | 180-250 | SK8010 | 120 (80-210) | 0.08 (0.04-0.15) |