Iscar 10pc Carbide Insert WNMG3-1-GN IC8250

Grade : IC8250

A tough substrate with a cobalt enriched layer combined with multi-layer CVD coating. Recommended for general use machining of steel in a wide range of conditions, featuring high toughness and wear resistance.

ISO Range – P/M/K (P10-P35)(M05-M20)

ISO Range – N/S/H

Grade or Coating Type CVD

Coating Layers TiCN+Al2O3+TiN

Find group of specific workpiece material (opens in a new window)

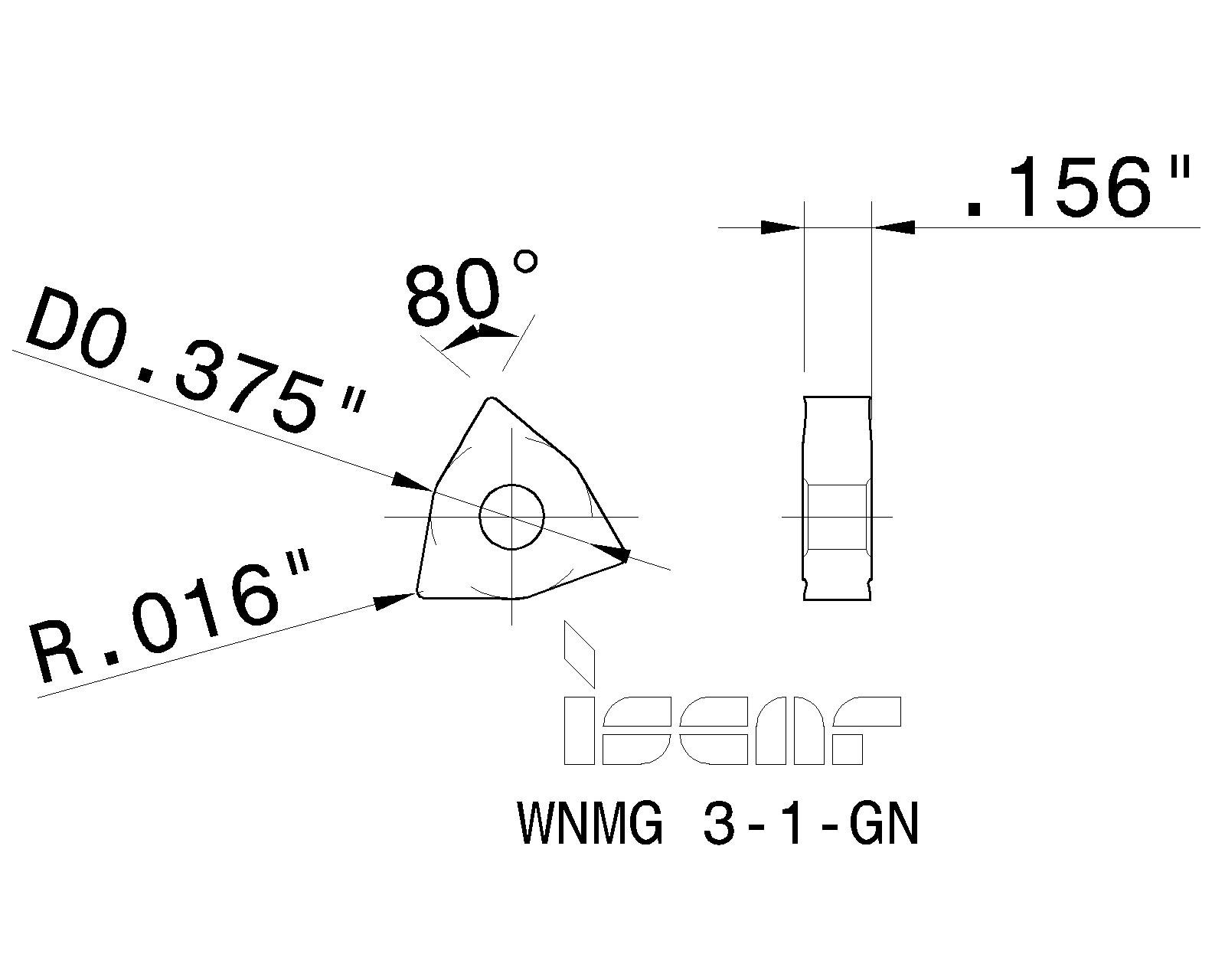

Inch carbide insert dimension

| L | IC | S | RE | ft (min) |

ft (max) |

ap (min) |

ap (max) |

|---|---|---|---|---|---|---|---|

| .257 | .375 | .156 | .0157 | .0055 | .0157 | .039 | .138 |

Metric Carbide Insert Dimension

| L | IC | S | RE | ft (min) |

ft (max) |

ap (min) |

ap (max) |

|---|---|---|---|---|---|---|---|

| 6.52 | 9.52 | 3.97 | 0.40 | 0.14 | 0.40 | 1.00 | 3.50 |

Grade Name: IC8250

Insert Material: CARBIDE – CVD COATED

ISO Range: P10-35 M05-20

Coating: MTCVD TiCN/Al2O3

Material Description: Steel, Stainless

Grade Description: ‘A tough substrate with a cobalt enriched layer combined with improved MTCVD TiCN and a thick alpha Al2O3 CVD coating. Recommended for general use machining of steel in a wide range of conditions, featuring high toughness and resistance to chipping and plastic deformation.’

Insert Material: CARBIDE – CVD COATED

ISO Range: P10-35 M05-20

Coating: MTCVD TiCN/Al2O3

Material Description: Steel, Stainless

Grade Description: ‘A tough substrate with a cobalt enriched layer combined with improved MTCVD TiCN and a thick alpha Al2O3 CVD coating. Recommended for general use machining of steel in a wide range of conditions, featuring high toughness and resistance to chipping and plastic deformation.’