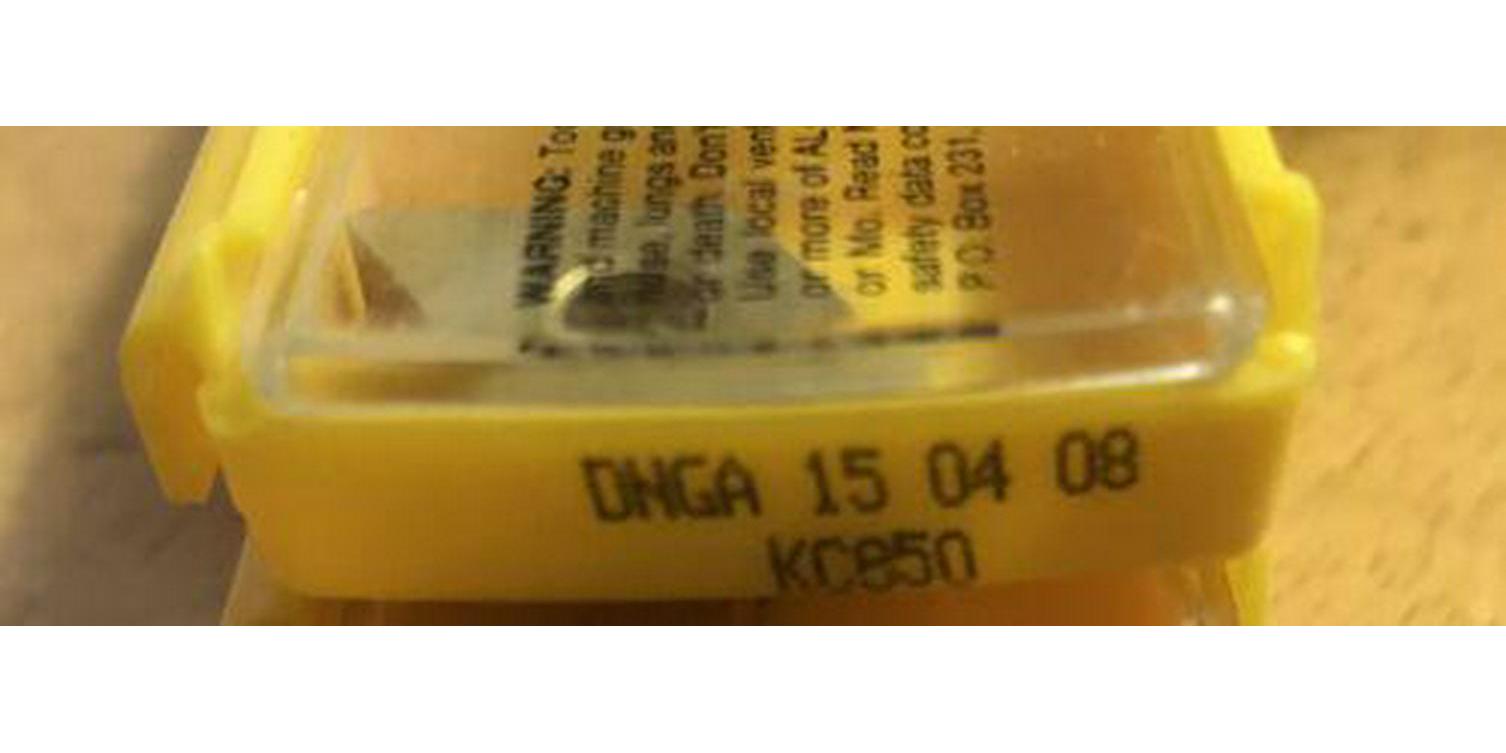

Kennametal DNGA 432 Kenloc Negative Carbide Insert

| Inscribed Circle (Decimal Inch) | 0.5000 |

| Insert Material | Carbide |

| Corner Radius (Inch) | 1/32 |

| Corner Radius (Decimal Inch) | 0.0312; 0.0312 in; 1/32 in |

| Length Range (Decimal Inch) | 0.6000 – 0.6500 |

| Coating Process | CVD |

| Hole Diameter (Decimal Inch) | 0.2031 |

| Rake | Negative |

KC850 – turning & boring, profiling, grooving C5 – C6 M30 – M45 and P25- P45

Composition: A tri-phase coating on an extra strong, cobalt-enriched substrate.

Three coating layers; TiN outside, TiCN middle, TiC inside

Application: Grade KC850 has long been considered the industry’s leading choice

for general purpose machining of many workpiece materials. With the advent of higher

machine tool spindle speeds, today it finds its best application in heavy cutting of low,

medium, and high carbon steels, as well as medium hardness alloy and tool steels.

Excellent thermal and mechanical shock resistance makes grade KC850 ideally suited

for difficult applications with interruptions. Consider using grade KC935 for lighter cuts.