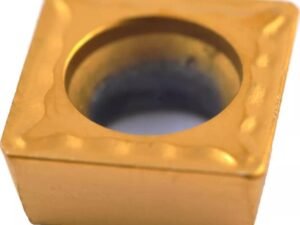

Indexable Tunsgten Carbide Insert 10pc Pack TNMG160404-TF IC907

Double-sided, triangular insert, positive rake angle that varies along the edge to negative in order to prevent chipping. Special design reduces cratering. Used for carbon and alloy steel, stainless steel and high temp. alloys.

| L | IC | S | RE | ft

(min) | ft

(max) | ap

(min) | ap

(max) |

|---|

| 16.50 | 9.52 | 4.76 | 0.40 | 0.12 | 0.30 | 1.00 | 3.00 |

A tough sub-micron substrate, PVD coated. Suitable for low-to-medium cutting speeds. Developed for machining of heat resistant alloys, austenitic stainless steel and hard steel.

| ISO Range – P/M/K | (P10-P30)(M05-M20)(K15-K30) |

| ISO Range – N/S/H | (H05-H15)(S05-S20)(N05-N20) |

| Grade or Coating Type | PVD |

| Coating Layers | TiAlN+TiN |

| Cutting Speed Suggestion Manufacture for: TNMG 160404 |

| ISO | Material | Material Designation | Material Condition | Hardness | Cutting Speed Recommendations (Vc) |

|---|

| P | 1 | Non-alloy steel and cast steel, free cutting steel <0.25% C | Annealed | 125 HB | 120-200 m/min | | P | 2 | Non-alloy steel and cast steel, free cutting steel >=0.25% C | Annealed | 190 HB | 100-170 m/min | | P | 3 | Non-alloy steel and cast steel, free cutting steel <0.55% C | Quenched and tempered | 250 HB | 80-150 m/min | | P | 4 | Non-alloy steel and cast steel, free cutting steel >=0.55% C | Annealed | 220 HB | 90-160 m/min | | P | 5 | Non-alloy steel and cast steel, free cutting steel >=0.55% C | Quenched and tempered. | 300 HB | 80-130 m/min | | P | 6 | Low alloy and cast steel (less than 5% of alloying elements) | Annealed | 200 HB | 80-150 m/min | | P | 7 | Low alloy and cast steel (less than 5% of alloying elements) | Quenched and tempered | 275 HB | 70-130 m/min | | P | 8 | Low alloy and cast steel (less than 5% of alloying elements) | Quenched and tempered | 300 HB | 60-120 m/min | | P | 9 | Low alloy and cast steel (less than 5% of alloying elements) | Quenched and tempered | 350 HB | 50-100 m/min | | P | 10 | High alloyed steel, cast steel and tool steel | Annealed | 200 HB | 80-130 m/min | | P | 11 | High alloyed steel, cast steel and tool steel | Quenched and tempered | 325 HB | 50-100 m/min | | P | 12 | Stainless steel and cast steel | Ferritic/martensitic | 200 HB | 170-265 m/min | | P | 13 | Stainless steel and cast steel | Martensitic | 240 HB | 140-245 m/min | | M | 14 | Stainless steel and cast steel | Austenitic | 180 HB | 100-280 m/min | | K | 15 | Grey cast iron (GG) | Pearlitic/ferritic | 180 HB | 30-140 m/min | | K | 16 | Grey cast iron (GG) | Pearlitic/martensitic | 260 HB | 30-140 m/min | | K | 17 | Nodular cast iron (GGG) | Ferritic | 160 HB | 30-140 m/min | | K | 18 | Nodular cast iron (GGG) | Pearlitic | 250 HB | 30-140 m/min | | K | 19 | Malleable cast iron | Ferritic | 130 HB | 30-140 m/min | | K | 20 | Malleable cast iron | Pearlitic | 230 HB | 30-140 m/min | | S | 31 | High temp. alloys Fe based | Annealed | 200 HB | 50-80 m/min | | S | 32 | High temp. alloys Fe based | Hardened | 280 HB | 40-65 m/min | | S | 33 | High temp. alloys Ni or Co based | Annealed | 250 HB | 45-60 m/min | | S | 34 | High temp. alloys. Ni or Co based | Cured | 350 HB | 35-45 m/min | | S | 35 | High temp. alloys. Ni or Co based | Cast | 320 HB | 30-50 m/min | | S | 36 | Titanium (pure) | Pure | 110 HB | 100-180 m/min | | S | 37 | Titanium alloys | Alpha+beta alloys | 310 HB | 50-55 m/min | | H | 38 | Hardened steel | Hardened | 55 HRC | 20-90 m/min | | H | 39 | Hardened steel | Hardened |

|