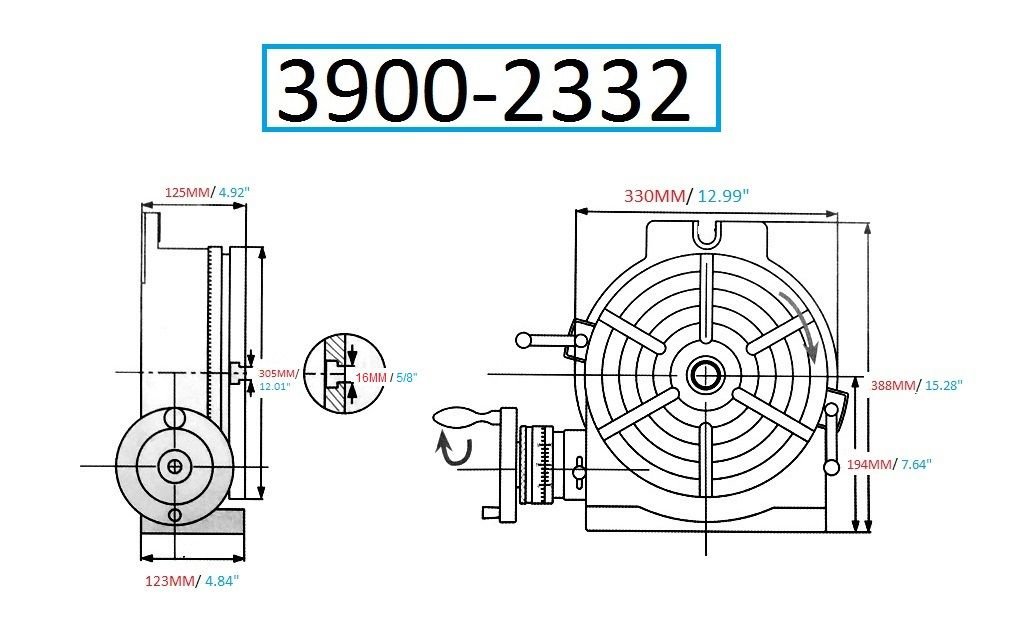

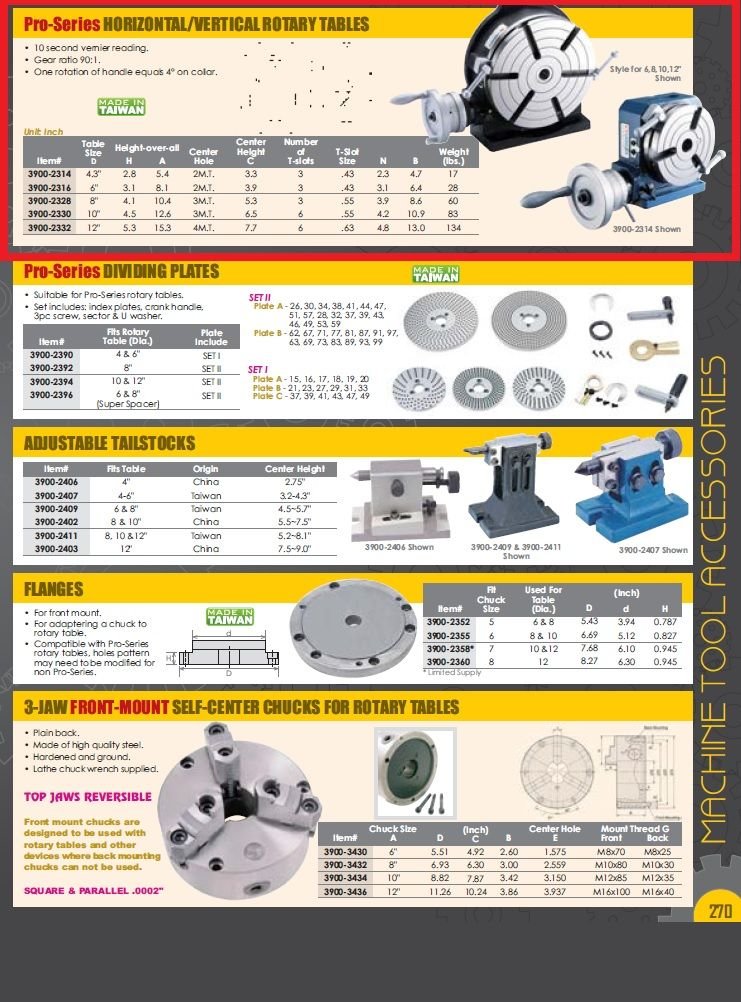

VERTEX 12″ HORIZONTAL/VERTICAL ROTARY TABLE (3900-2332)

Unlock a new level of accuracy and versatility in your metalworking projects with the VERTEX 12″ Horizontal/Vertical Rotary Table (Model # HV-12). Renowned globally for their uncompromising quality, Vertex High Precision Taiwanese Rotary Tables are the benchmark for machinists and fabricators demanding the best. Each table undergoes meticulous manufacturing processes, including precision grinding of the table surface, to ensure unparalleled accuracy and smooth operation.

Constructed from premium, high-density Meehanite cast iron, this robust rotary table offers exceptional rigidity and vibration dampening, crucial for maintaining tight tolerances even under heavy loads. Its ingenious design allows for both horizontal and vertical mounting, making it an indispensable tool for a vast array of machining applications, including intricate milling, precise drilling, accurate boring, and fine grinding.4 Engineered for seamless integration, it’s designed to be used effortlessly with front mount chucks.

Key Features & Specifications

The VERTEX 12″ Horizontal/Vertical Rotary Table is packed with features designed to enhance your productivity and the quality of your work:

- Premium Construction: Made from high-quality, high-density Meehanite cast iron for superior rigidity, vibration dampening, and long-term durability.

- Dual Orientation Versatility: Seamlessly switch between horizontal and vertical setups to accommodate diverse workpieces and machining operations.

- Exceptional Precision: Achieves high accuracy through meticulous manufacturing and precision-ground table surfaces.

- Fine Angular Control: Features a 10-second vernier reading and a precise 90:1 gear ratio, ensuring minute and accurate angular positioning for complex indexing tasks.

- Efficient Indexing: One full rotation of the handle precisely moves the collar by 4 degrees, simplifying multi-angle machining.

- Robust Load Capacities:

- Horizontal Load Capacity: 264 lbs (120 kg)10

- Vertical Load Capacity: 132 lbs (60 kg)11

- Optimized Workholding: Equipped with 6 T-slots (0.63″ / 16mm size) for secure and flexible workpiece clamping.12

- Industry-Standard Spindle: Features a 4MT (Morse Taper) center hole for compatibility with a wide range of tooling and accessories.13

- Compact & Functional Design:

- Overall Horizontal Height: 5.3″ (134.6 mm)14

- Overall Vertical Height: 15.3″ (388.6 mm)15

- Vertical Center Height: 7.7″ (195.6 mm)16

- Solid Build: Weighs 134 lbs (60.8 kg) (Shipping Weight: 137 lbs / 62.1 kg), reflecting its robust and stable construction.17

Unleash Your Machining Potential

The VERTEX 12″ Horizontal/Vertical Rotary Table isn’t just a tool; it’s an investment in expanded capabilities and new revenue streams. Here’s how this versatile rotary table can transform your operations and open up new sales opportunities:

- Precision Gear Cutting: Create custom gears, splines, and sprockets with unparalleled accuracy. Offer bespoke gear manufacturing services to local industries or specialty vehicle restorers.

- Fluting & Engraving: Produce decorative flutes on columns, handles, or shafts. Perfect for custom furniture components, architectural details, or artistic metalwork that commands premium pricing.

- Multi-Sided Machining (Indexing): Easily machine multiple faces of a workpiece without re-fixturing. This significantly reduces setup time and improves accuracy for projects like square or hexagonal components, manifold blocks, or complex jigs.

- Circular Slotting & Hole Patterns: Accurately drill hole patterns on a circular pitch, or mill radial slots in flanges, cam plates, and dials. Essential for industrial components, instrument panels, or custom machinery parts.

- Angled Drilling & Boring: Precisely bore or drill holes at specific angles relative to a central axis.18 This capability is vital for creating angled passages in engine components, specialized fittings, or complex tooling.

- Rotary Grinding: Achieve perfectly flat and parallel surfaces on circular parts, or grind precise contours. Ideal for finishing operations on high-tolerance components or sharpening custom cutting tools.

- Fixture & Jig Creation: Fabricate highly accurate and repeatable fixtures and jigs for your own production lines or as a service to other manufacturers, streamlining their processes.

- Educational & Prototyping: An excellent addition for vocational schools, engineering programs, and R&D departments where teaching precision machining and rapid prototyping of complex parts is essential.

Invest in the VERTEX 12″ Horizontal/Vertical Rotary Table today and elevate your workshop’s capabilities to handle more intricate, higher-value projects with confidence and precision.

Reviews

There are no reviews yet.