33″x 8″ Mill/Drill Weiss Machinery Benchtop Variable Speed Brushless Motor 2HP

The Weiss Mill VM32L is a high-quality milling machine that boasts a robust construction and precise performance. With a table size of 8 inches by 33 inches, it provides ample workspace for various milling tasks. Its design is ideal for both professional machinists and DIY enthusiasts who require accuracy and reliability in their machining projects.

The Weiss Mill VM32L features a durable cast iron construction, ensuring stability and durability. The machine is designed to withstand heavy-duty milling tasks and provide consistent performance over time. Its compact size makes it suitable for small workshops or garage setups.

Best milling option manufacture by Weiss Machinery in China, but comparison quality is good. This machine is easy for convert in Mini cnc milling.

Weiss Machinery is same maufacturer than Grizzly, jet, Precision Matthews, Enco, Baileigh and others similars brands

1. Table size: 33-5/64″ x 8-17/64″

2. Table travel: 22-53/64″ x 8-5/64″

3. Max. drilling capacity: 1-3/16″

4. R8 spindle

5. Power: single phase 110V 2HP

6. Absolute operating silence (no gear)

7. Digital display RPM

8. Electronic ruler display spindle feed

Description

1. Variable speed enables to operate easily.

2. Spindle is supported by high precision taper roller bearing.

3. Single speed belt drive provide more quiet and easy operation.

4. Mill head can be tilled 90 degree.

5. Bigger table provides more capacity.

6. The dovetail rails are equipped with adjustable taper inserts for greater wear resistance.

7. Precision manual fine down feed.

8. An electronic ruler is used for the spindle depth, accurately drilling, the minimum counting depth is 0.00004″ or 0.001mm.

9. The feed length of the spindle can be precisely adjusted with the minimum feed rate up to 0.0008″ or 0.02mm.

10. Minimum scale for hand wheel 0.002″.

11. Direct transmission by toothed belt.

Technical Details

Best Mill for CNC Conversion

VM32L is good mill for convert in cnc machine only need replace table screws for balls screws and can adapter nema or servo motors kit with simple adapter

| Model | VM32L | |

| Max. Drilling Capacity | 1-3/16″ | 30mm |

| Max. End Milling Capacity | 25/32″ | 20mm |

| Max. Face Milling Capacity | 3″ | 76mm |

| T-Slot Size | 3 @ 35/64″ slots | 3 @ 14mm slots |

| T-Slot Centers | 2-1/2″ | 63mm |

| Table Size | 33-5/64″ × 8-17/64″ | 840 × 210mm |

| Table Travel (X, Y) | 22-53/64″ × 8-5/64″ | 580 × 205mm |

| X/Y-Axis Travel per Handwheel Revolution | 0.1″ | |

| Spindle Stroke | 2-3/4″ | 70mm |

| Distance from Spindle to Column | 8-17/64″ | 210mm |

| Distance from Spindle nose to table | 18-1/2″ | 470mm |

| Spindle Drawbar Thread Size | 7/16″ | |

| Spindle Drawbar Length | 12-1/2″ | |

| Head Tilt (Left/Right) | 90 Deg. | |

| Spindle Taper | R8 | |

| Number of Spindle Speeds | Variable | |

| Vertical Spindle Speeds | 100 – 2250 RPM | |

| Motor Type | Brushless 2HP | |

| Power Requirement | Single Phase 110V 60Hz | |

| Rated Current | 10A | |

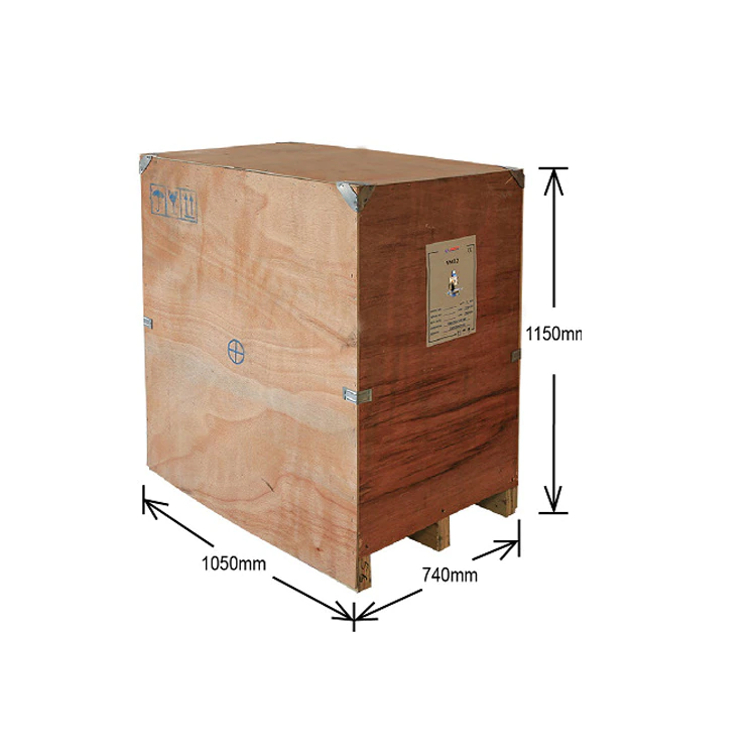

| Packing Size | 39-5/8″ × 28-3/4″ × 46″ | |

| Net Weight | 445.4 lbs. | |

| Gross Weight | 551.3 lbs. | |

Additional Information

STANDARD EQUIPMENT:

- – Drill chuck with key capacity 1/64″ to 25/64″

- – Drill bits set

- – Tool box

- – Technical documentation

Finance Low Payment Available

APPLY WITH INSTANT DECISION

Our simple electronic application will give you an instant credit decision within hours of submitting. We approve financing from $1,000 and up.

Benefit from your Taxes

The government created a tax program called Section 179 that allows you to write off the full financed equipment cost in the year you buy it. Now you don’t have to wait years to receive your tax deductions on your new equipment!

✓ Save Thousands

✓ Cash For Emergencies

✓ Reinvest Your Cash

Apply Today Online Month Payment CLICK NOW

A brushless motor milling machine is a type of milling machine that utilizes a brushless motor as its power source, instead of a traditional brushed motor. This type of motor offers several advantageous features, including:

High efficiency: Brushless motors are known for their high efficiency due to their advanced design and lack of brushes, which minimizes energy loss from friction and heat. This results in improved power utilization and reduced energy consumption, making a brushless motor milling machine more cost-effective in the long run.

Longer lifespan: Brushless motors have a longer lifespan compared to brushed motors since they do not have brushes that can wear out over time. This means less maintenance and replacement costs, making a brushless motor milling machine a durable and reliable option for machining tasks.

Higher torque and precision: Brushless motors are capable of delivering higher torque and precision, making them ideal for milling operations that require high levels of power and accuracy. They can maintain consistent speed and torque even at low speeds, ensuring smooth and precise cutting operations.

Quieter operation: Brushless motors are typically quieter than brushed motors, as they do not produce the same level of mechanical noise from brushes rubbing against commutators. This results in a quieter operation, which can be beneficial in noise-sensitive environments such as workshops or production facilities.

Digital control: Brushless motor milling machines often come with advanced digital control systems that allow for precise speed and feed rate adjustments. This enables fine-tuning of cutting parameters, resulting in improved machining accuracy and surface finish.

Reduced maintenance: Since brushless motors do not have brushes that can wear out, they require less maintenance compared to brushed motors. This can result in lower maintenance costs and less downtime, making a brushless motor milling machine a convenient and reliable choice for machining operations.

In summary, a milling machine equipped with a brushless motor offers several advantageous features including high efficiency, longer lifespan, higher torque and precision, quieter operation, digital control, and reduced maintenance. These features make it a reliable and cost-effective choice for machining tasks that require precision and performance.

WARRANTY: 1-YEAR Warranty For Parts, Service and Repair.