STU Shop Tool Usa Solutions industry

Introduction

When working on heavy-duty engines like those in trucks or tractors, precise internal measurements are everything. In my experience, especially when dealing with deep cylinders where standard tools fall short, a 12-inch long telescoping cylinder bore gage set becomes essential.

Over the years, I’ve used the 6-piece 5/16″ to 6″ T-handle telescoping gage set to inspect engine bores where depth and precision matter. In this article, I’ll walk you through why these tools matter, when to use them, and how they can save you time and prevent costly engine rebuild errors.

What Is a Telescoping Bore Gage?

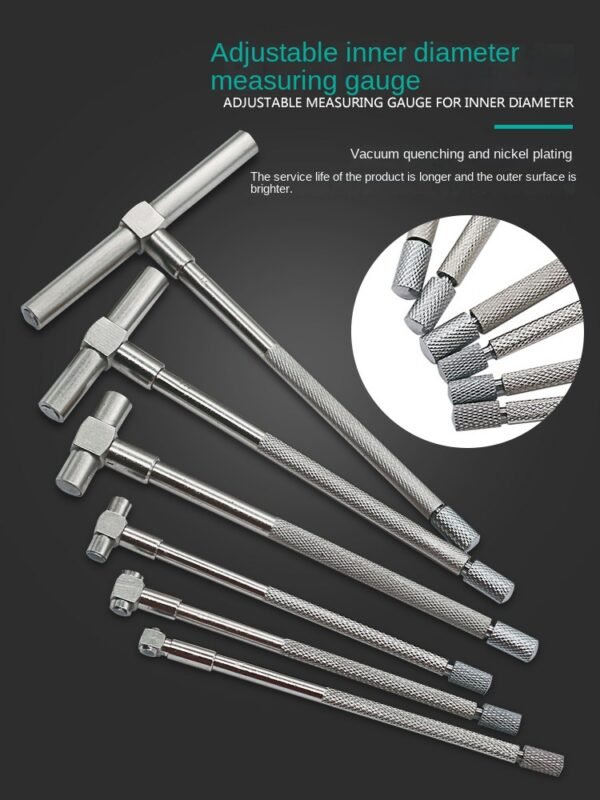

A telescoping bore gage (also called a T-bore gage or cylinder gage) is a precision measurement tool designed to gauge the internal diameter of holes, specifically bores in engines or machinery. It works by expanding two spring-loaded arms that contact the inside surface of the cylinder, which are then measured with a micrometer.

This particular set ranges from 5/16″ to 6″ and has an extra-long 12″ handle, making it ideal for deep cylinders that regular gages can’t reach.

Why I Use the 12-Inch Long Version

In many of the engines I work on, especially truck and tractor motors, the cylinders are deep and narrow. Most standard bore gages max out at 6 inches of reach, which just doesn’t cut it.

With the 12″ long telescoping gages, I can comfortably reach the base of a cylinder and get a consistent measurement without tilting or repositioning the tool. That ensures that the readings are accurate, repeatable, and aligned with the bore axis.

Features of the 6 Pc Set I Use

Range: 5/16″ – 6″

Handle Length: 12″ (great for deep bores)

Number of Gages: 6

Construction: Hardened steel, satin chrome finish

Locking Knob: Holds arms in place for consistent measurement

Storage Case: Included

How I Take Cylinder Measurements

Select the correct gage size for the bore.

Compress the arms and insert it into the cylinder.

Let the arms expand against the walls.

Lock the arms using the knurled knob.

Gently remove the gage without changing the angle.

Use a micrometer to measure the maximum span of the gage arms.

This method allows for incredibly precise internal diameter readings, even in deep engine cylinders.

Real-World Use Case

Just last month, I was rebuilding a diesel engine for a Mack truck. The cylinder bores were deep and had minor wear. Using my 12″ telescoping gage, I discovered a slight ovality that wouldn’t have been visible without reaching to the base of the bore. That early detection saved the customer thousands by catching the problem before assembly.