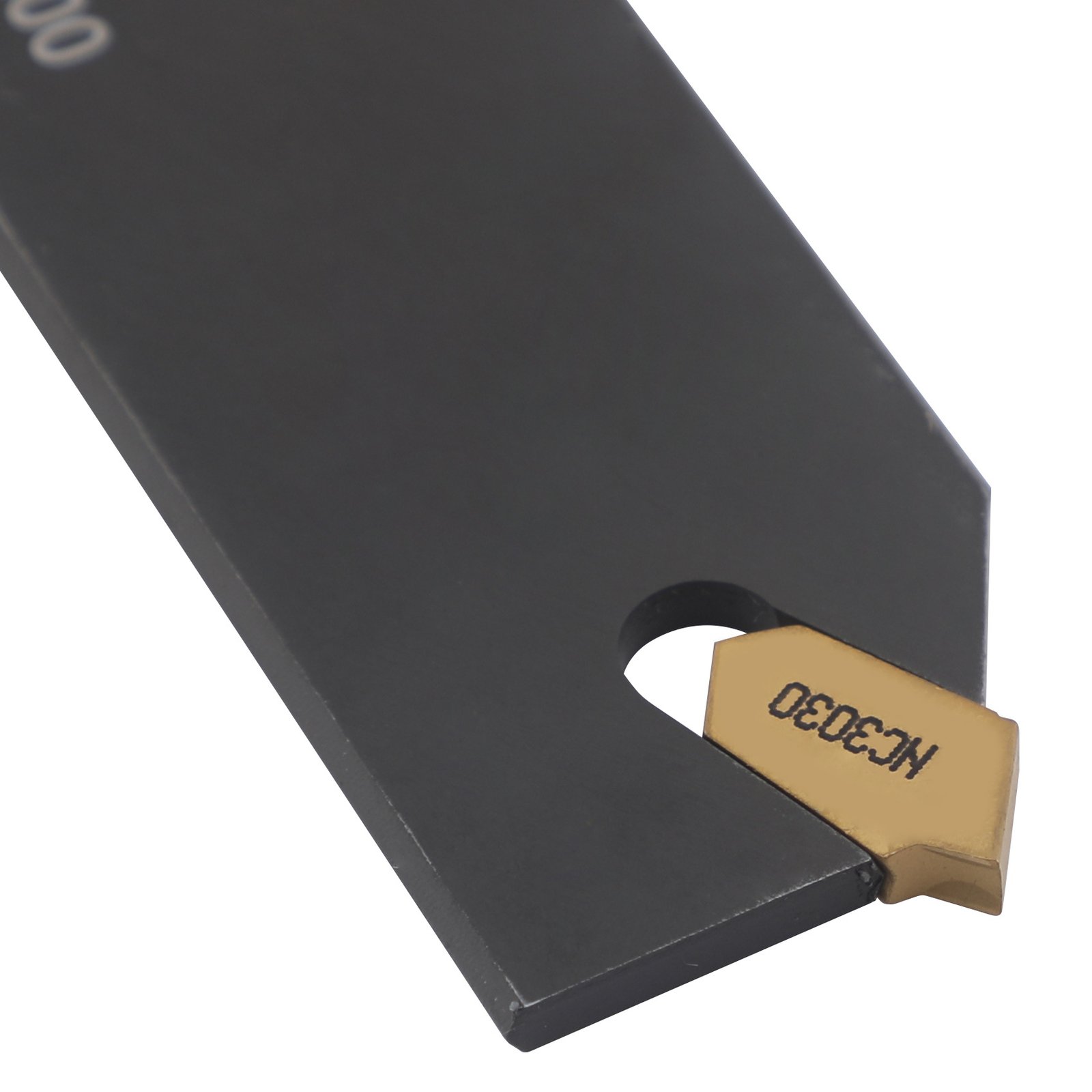

Introducing the STU SHOP TOOL USA SPB326 26mm Lathe Tool Holder Blade, accompanied by 10 premium GTN-3 SP300 carbide inserts with TiN coating. This high-performance turning tool holder is meticulously engineered for precision CNC lathe operations, excelling in parting-off and grooving tasks.

Key Features:

Robust Construction: The SPB326 blade is crafted from high-quality metal, measuring 110mm in length, 26mm in height, and 2.4mm in thickness, ensuring exceptional durability and stability during machining operations.

Superior Carbide Inserts:The included GTN-3 SP300 inserts are made from coated carbide, each with a width of approximately 3mm. The TiN (Titanium Nitride) coating enhances wear resistance and prolongs tool life, delivering consistent and reliable performance.

Enhanced Performance: Designed for high cutting efficiency, these inserts offer excellent precision and toughness. They exhibit strong shock resistance and thermal stability, making them ideal for semi-finishing steel applications.

Versatile Application: This tool holder blade is compatible with standard cut-off inserts, making it suitable for a wide range of parting and grooving operations on CNC lathes.

Elevate your machining capabilities with the STU SHOP TOOL USA SPB326 Lathe Tool Holder Blade and GTN-3 SP300 carbide inserts. Experience precision, durability, and efficiency in your CNC lathe operations, ensuring optimal performance in all your parting-off and grooving tasks.

Cutting Recommendations for SP300 STU-SHopToolUsa Carbide Insert (PVD – Silicon + TiN, P10-P30)

The SP300 STU-SHopToolUsa carbide insert, coated with PVD (Silicon + TiN) in a golden yellow finish, is designed for semi-finishing and finishing operations in steel machining (P10-P30 range). Its high-hardness TiN coating with silicon provides low friction, excellent surface finish, and wear detection capability, making it ideal for precision grooving and milling.

1. Cutting Speed (Vc) – Based on Steel Type

- P10 (Low Carbon & Soft Steel, e.g., 1018, 1020, A36): 180–300 m/min

- P20 (Medium Carbon & Alloy Steel, e.g., 1045, 4140, 4340): 120–250 m/min

- P30 (Harder & Tougher Steel, e.g., 1095, 8620, 52100): 80–180 m/min

2. Feed Rate (f) – Based on Application

- Finishing: 0.05–0.15 mm/rev (for smooth surfaces and tight tolerances)

- Semi-Finishing: 0.15–0.30 mm/rev (for balanced material removal and finish)

3. Depth of Cut (ap) – Grooving & Milling

- Grooving Depth: 0.5–3.0 mm (depending on machine stability and groove width)

- Milling Depth: 0.2–1.5 mm (for precision finishing passes)

4. Best Practices for Optimal Performance

✅ Use Coolant – Reduces heat buildup and enhances tool life.

✅ Optimize Feed Rate – Lower feed for fine finishes, higher for efficiency.

✅ Avoid Excessive Depths – Helps maintain edge integrity and prevents chipping.

✅ Check Wear Regularly – TiN coating helps visually detect insert wear.

✅ Ensure Rigid Setup – Minimizes vibration, improving accuracy and tool longevity.

This insert is ideal for precision grooving and semi-finishing to finishing operations in steel, ensuring low friction, high-quality surface finishes, and long tool life. 🚀