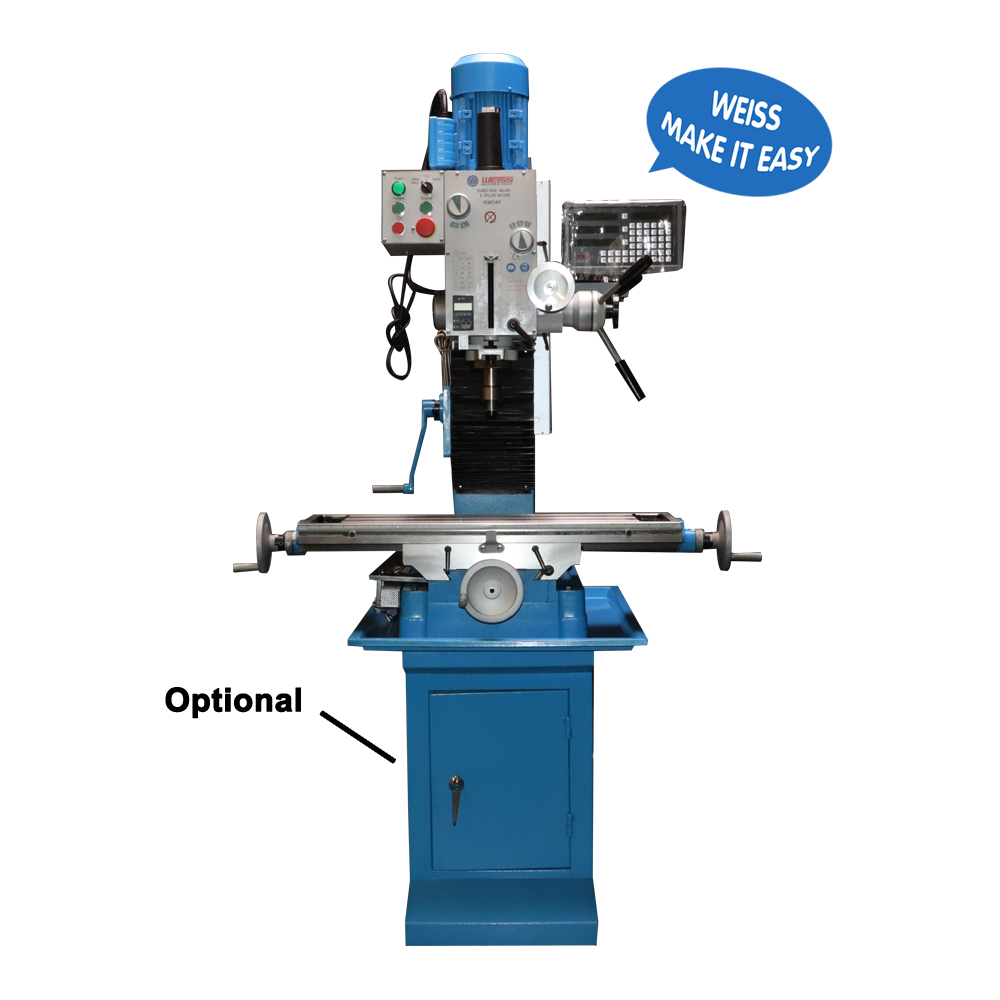

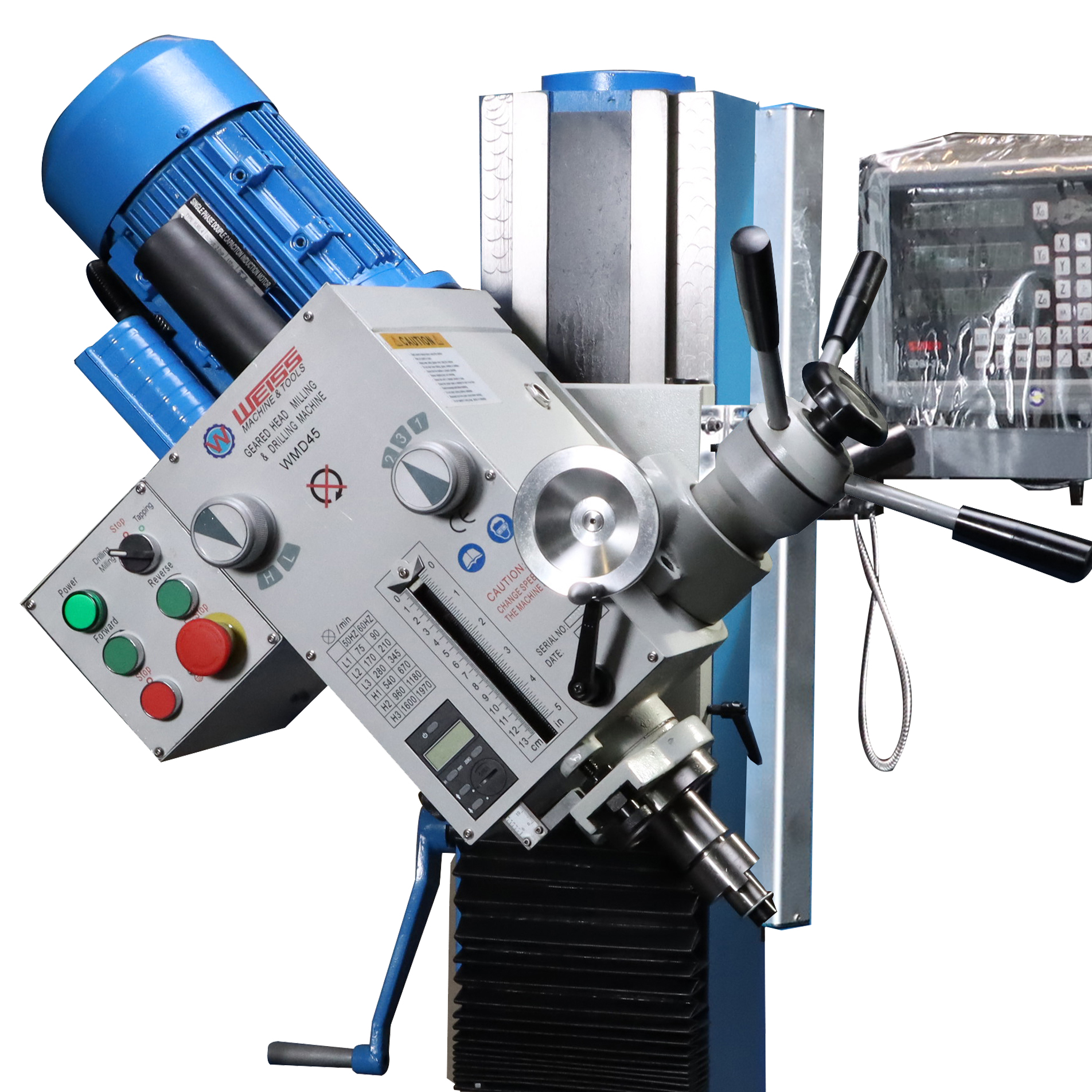

WEISS WMD45 9-1/2″ x 32″ Gear Head Milling Machine 2HP(1500W) Milling&Drilling Machine, Gear Drive Mill/Drill with R8 Spindle& SINO 3-Axis DRO

1. WEISS heavy class milling machine for more rigidity and greater cutting ability.

2. Larger travels and work area with 9-1/2″ x 32″ worktable

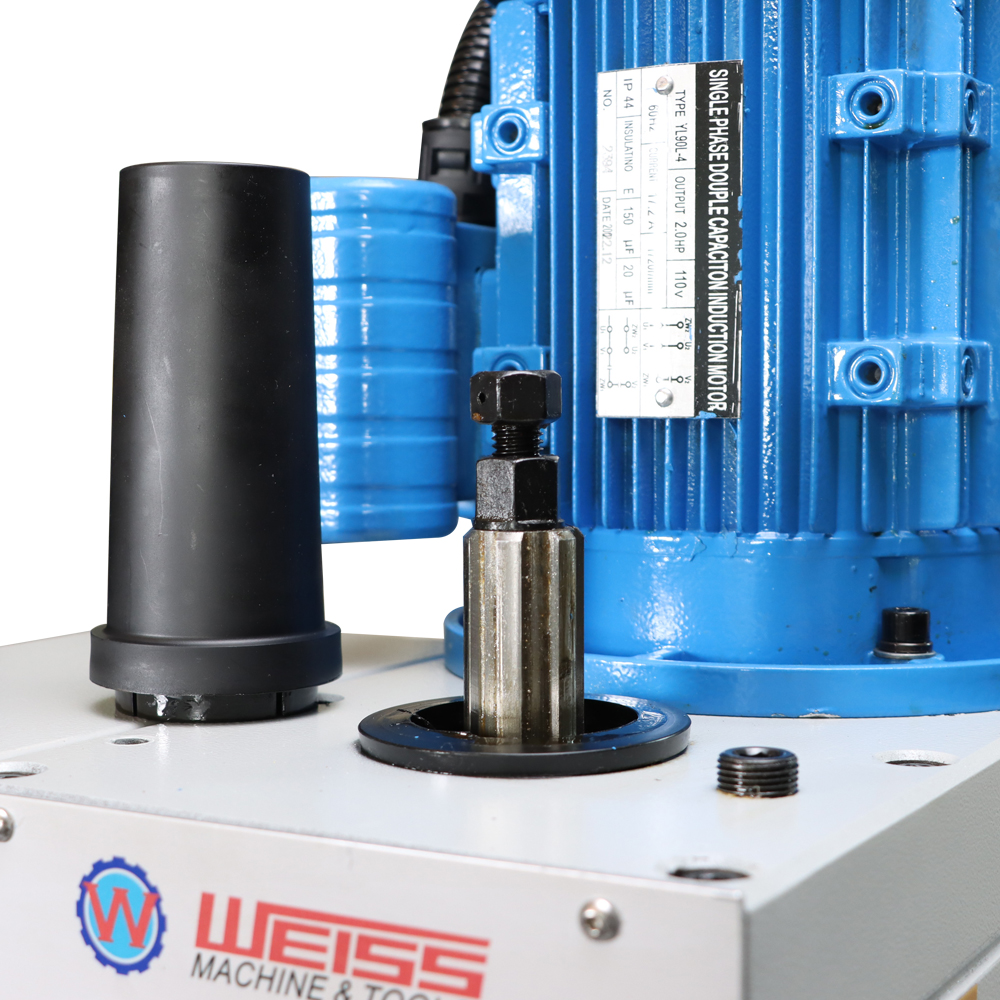

3. Big powerful 2 HP (1500W) with R8 spindle taper

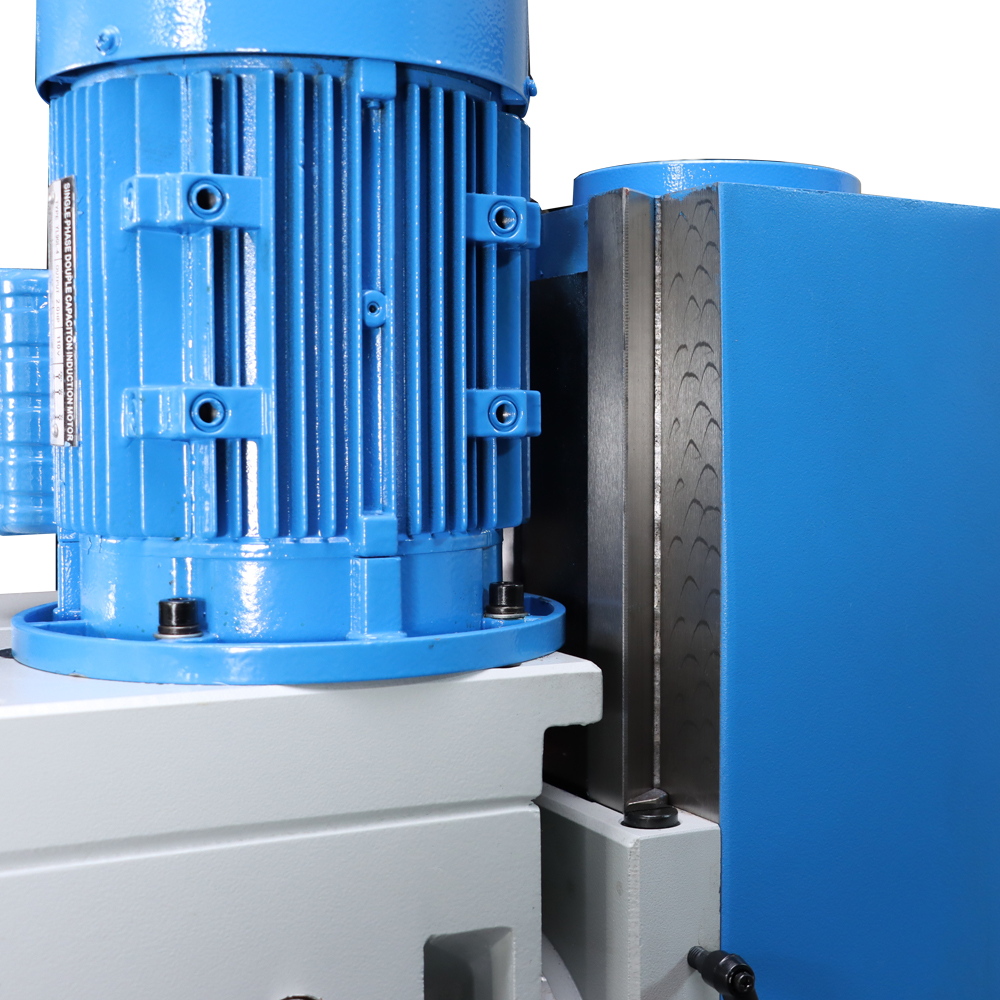

4. Six speeds gear drive system with 90-1970 RPM speed, provides easy and reliable operation

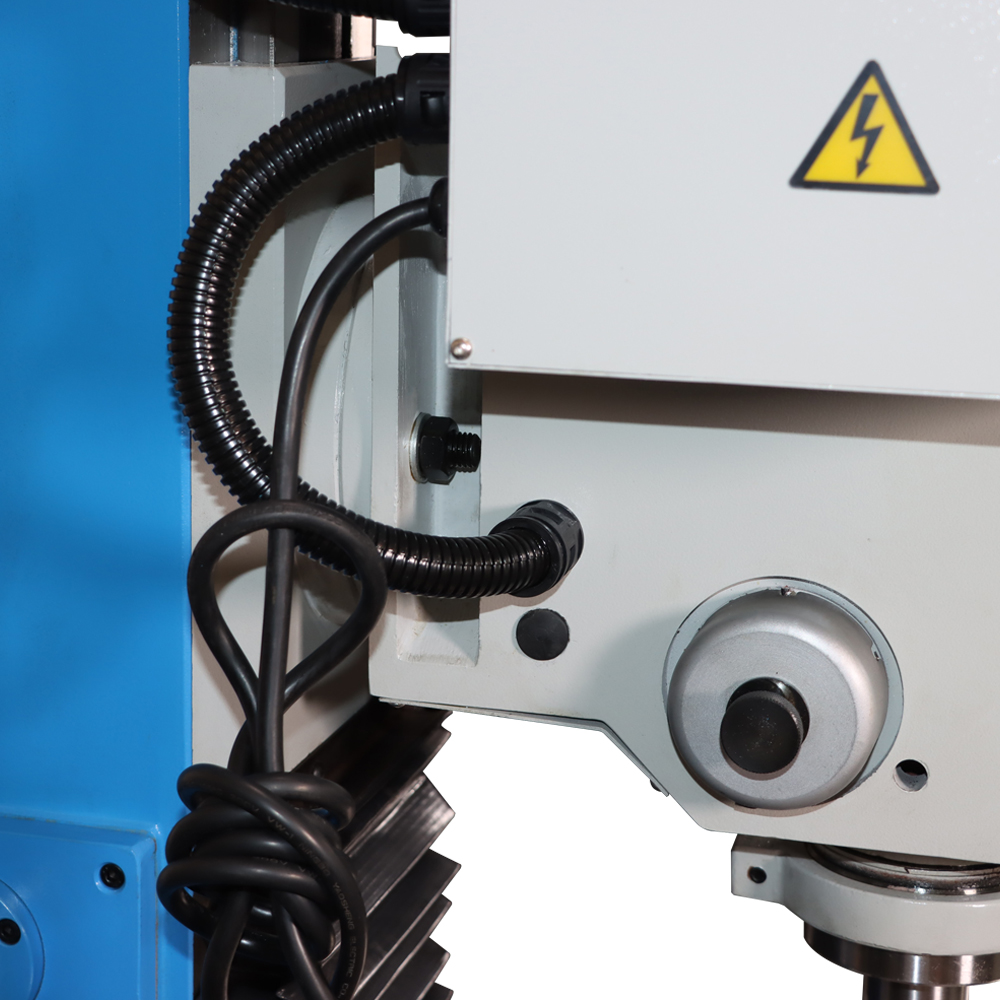

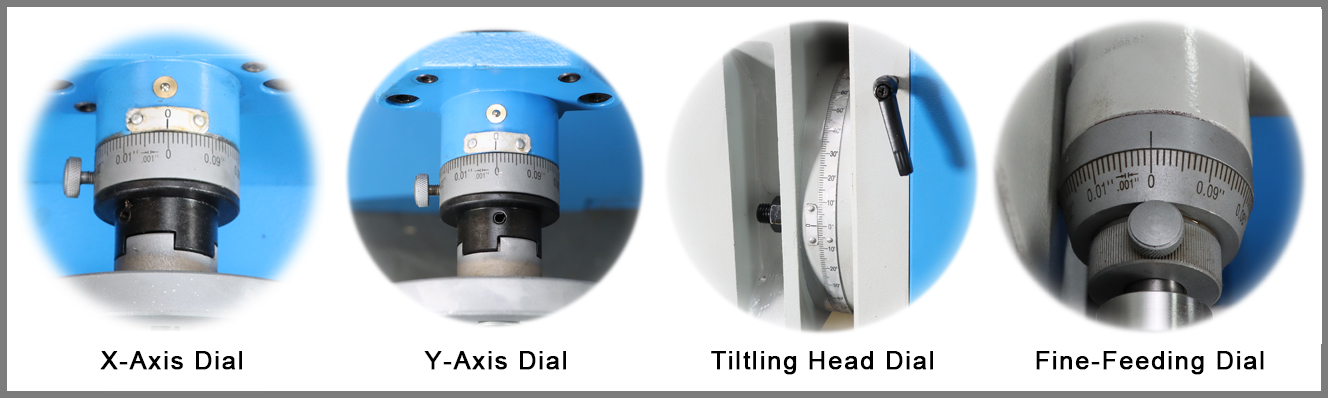

5. Super-rigid precision-ground dovetail headstock column and table ways, precision handwheel control for X, Y, and Z-axis

6. All leadscrews are true inch pitch screws, larger dials with 0.001″ graduate for easier reading

7. 3-axis SINO DRO system with grating scale

Weiss WMD45 Drilling Milling Operation

Technical Details

| Model | WMD45-DRO | |

| Max. Drilling Capacity | 45 mm | 17-3/4″ |

| Max. End Milling Capacity | 32 mm | 1-1/4″ |

| Max. Face Milling Capacity | 80 mm | 3-3/16″ |

| Table Size | 800 x 240 mm | 31-1/2″ x 9-1/2″ |

| Cross Travel | 230 mm | 9″ |

| Longitudinal Travel | 560 mm | 22″ |

| Spindle Taper | R8 | |

| Vertical Travel | 300mm | 11-7/8″ |

| Spindle Stroke | 120 mm | 4-3/4″ |

| T-slot | 3 x 14 mm | 1/8″ x 9/16″ |

| Step of Spindle Speeds | 6 | |

| Range of Spindle Speeds | 90 – 1920 RPM | |

| Head Tilt | 45 degrees left & right | |

| Distance from Spindle to Column | 260 mm | 10-1/4″ |

| Distance from Spindle Nose to Table | 470 mm | 18-1/2″ |

| Motor | 1.5KW | 2Hp |

| Power Requirement | Single Phase 110V 60Hz | |

| Rated Current | 10A | |

| Packing Size | 57″ x 28.3″ x 27.5″ | |

| Net Weight | 540 lbs. | |

| Gross Weight | 576 lbs. | |

Additional Information

STANDARD EQUIPMENT:

– Keyless Drill chuck capacity 5/8″ with B16 taper

– Drill chuck arbor R8/B16

– Spindle sleeve R8/MT3

– Spindle sleeve MT3/MT2

– 7/16″-20 Drawbar

– Toobox & tools

– Technical documentation

– 3-axis SINO DRO

· WMD45-D Heavy-Duty Mill/Drill with tapping function& 3-Axis DRO(SINO)

· Spindle is supported by high-precision P5 spindle bearings

· Spindle movement can be monitored on depth ruler in both inch or metric way

WMD45-D precision manual fine down feed can be adjusted with the min. feed rate up to 0.001″

· Six speeds gear drive system provides larger torque and easy operation.

· Gearbox levers make it chang spindle speeds fast and easily.

All leadscrews are true inch pitch screws. Large dials with 0.001″ graduation for easier reading

Comparing a drilling milling machine with a head that can be tilted 45 degrees and one without a head that can be tilted 45 degrees:

1. **Versatility of Operations**:

– **With Tilted Head**: A drilling milling machine with a head that can be tilted 45 degrees offers enhanced versatility. By tilting the head, you can perform angled drilling, milling, and slotting operations, expanding the range of possible tasks and accommodating various workpiece angles.

– **Without Tilted Head**: A milling machine without a head that can be tilted 45 degrees may have limitations in handling angled drilling or milling operations. It might be suitable for standard vertical drilling and milling tasks but might require additional setup and fixtures for angled operations.

2. **Complexity of Setup**:

– **With Tilted Head**: Machines with a tiltable head often have a straightforward setup for angled operations. The head can be easily adjusted to the desired angle, making it efficient for quick changes between tasks.

– **Without Tilted Head**: In contrast, machines without a tiltable head may require repositioning the workpiece or utilizing special fixtures to achieve angled drilling or milling. This additional setup process can be more time-consuming and labor-intensive.

3. **Workspace Accessibility**:

– **With Tilted Head**: When the machine’s head can be tilted, it provides better accessibility to the workpiece from different angles. This is advantageous for machining complex shapes or hard-to-reach areas.

– **Without Tilted Head**: A milling machine without a tiltable head might have limited access to certain parts of the workpiece, especially when dealing with intricate designs or multi-sided machining.

4. **Accuracy and Precision**:

– **With Tilted Head**: Tilted heads can maintain high levels of accuracy and precision in angled operations, thanks to their built-in mechanisms designed to secure the head firmly at the desired angle.

– **Without Tilted Head**: Achieving the same level of accuracy in angled operations without a tiltable head might be more challenging, as it relies on external fixtures or alignment methods.

5. **Cost and Space Considerations**:

– **With Tilted Head**: Drilling milling machines with tiltable heads tend to be more expensive due to the added mechanical components and engineering required to support head tilting functionality.

– **Without Tilted Head**: Milling machines without a tiltable head are often more cost-effective and require less space due to their simpler design.

Ultimately, the choice between a drilling milling machine with a tiltable head and one without a tiltable head depends on the specific machining needs of the user. For applications that involve a significant amount of angled drilling and milling work, a machine with a tiltable head can offer substantial advantages in terms of efficiency and versatility. However, for simpler, less frequent angled operations, a machine without a tiltable head may be a more practical and economical choice.